Agriculture Reference

In-Depth Information

ISO 22000:2005 and HACCP

The aim of the new ISO 22000:2005 standard was to put to-

gether a common global framework of safety requirements

applicable to all organizations involved in the food supply

chain, including primary production, processing, distribu-

tion, and any other related operations. ISO 22000:2005

utilizes ISO 9001:2000 as an organizational tool for

managing the implementation of HACCP. Overall, ISO

22000:2005 provides an effective framework for food

safety management and proper communication along the

entire food supply chain, in conjunction with rapid con-

trol of food safety hazards. ISO 22000:2005 requires iden-

tification of critical control precautions, implementation,

monitoring, evaluation and analysis, and improvement and

updating according to internal and external conditions of all

potential threats to the food chain (input, process, distribu-

tion). Until now, monitoring and evaluation of precautions

for prerequisites (glass control, control of cutting equip-

ment, chemical stuff, etc.) were not emphasized during the

audits of HACCP standards such as TSE 13001 and DS

3027. Moreover, it was the first time that a HACCP stan-

dard clearly mentioned that there should be two types of

control mechanisms. The aim of PRPs and CCPs is to con-

trol, eliminate, or minimize potential threats at acceptable

limits (MC, 2010). This allows every type of organization in

the supply chain—from primary producers to food proces-

sors to storage and transportation companies to retail and

food service outlets and even to producers of equipment

used in food processing—to implement a food safety man-

agement system. ISO 22000 incorporates the principles of

HACCP and addresses the requirements of several impor-

tant standards (British Retail Consortium [BRC], Interna-

tional Food System [IFS], and FSIS) in a single source doc-

ument. A huge plus of ISO 22000 is that it parallels the ISO

9001:2000 QMS standard, which is already being widely

implemented in many types of industry. Therefore, food

companies wishing to get certified with ISO 22000 will

find doing so relatively easy, provided they have already

been certified to ISO 9001. Although food safety cannot be

guaranteed only by getting the ISO 22000 certificate, im-

plementation of ISO 22000 and compliance throughout the

food supply chain are bound to make consumers more con-

fident that the food they purchase is safe, irrespective of its

origin, processing, and transportation (Anon, 2005). The re-

quirements of ISO 22000 are generic and applicable to any

organization involved in the food chain, irrespective of size

and complexity. Organizations within the food chain cover

a wide range, from feed producers and primary producers

to food manufacturers, transport and storage operators and

subcontractors, and retail food service outlets (including

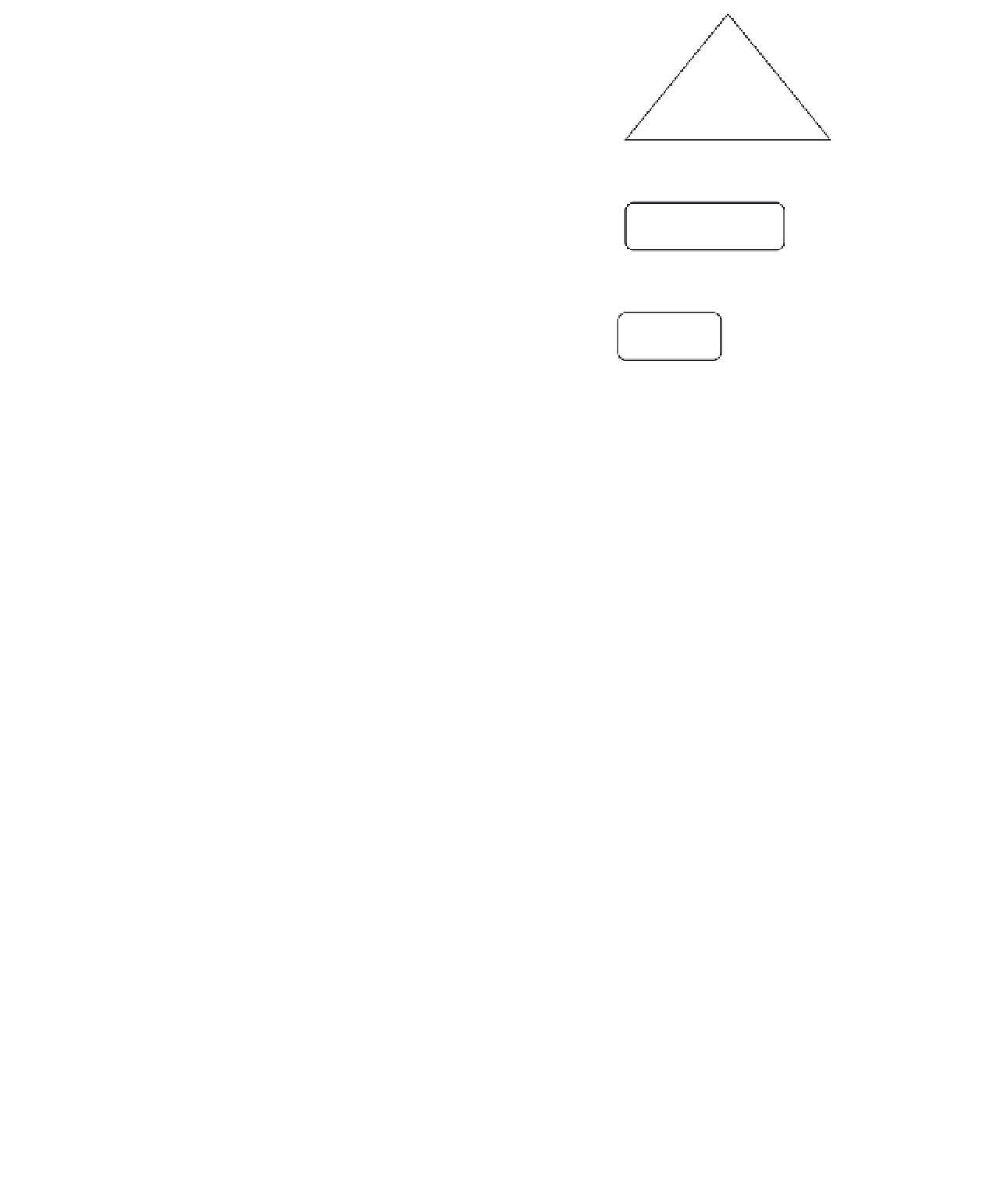

QMS or

ISO 22000:2005

TFS

HACCP

PRPs

Figure 6.2.

Conceptual framework of HACCP,

prerequisite programs (PRPs), and total food safety

(TFS) in relation to quality management system

(source: Sun and Ockerman, 2005).

interrelated organizations such as equipment manufactur-

ers, packaging materials, cleaning chemicals, additives, and

ingredients). These organizations are expected to take into

account the safety hazards of the final food product of

the chain and undertake measures to control these hazards

(Anon, 2004). A tentative correlation of HACCP, PRPs,

and total food safety within the frame of ISO 22000:2005

or QMS is shown in Fig. 6.2.

HACCP APPLICATION IN TROPICAL

FRUITS PROCESSING

Critical steps for developing HACCP program

For developing an effective HACCP program, the following

steps should be followed:

Form a multidisciplinary team considering factory man-

agement, scientists, engineers, and bookkeepers so that

reliable input can be provided at periodic HACCP meet-

ings. In the case of fruit processing, people with knowl-

edge of fruit growing, handling, storage, and distribution

should be included to provide input about local condi-

tions.

Appoint an external safety consultant with technical

knowledge to provide guidance at the HACCP meet-

ings. The consultant can coordinate external testing and

laboratory services and discuss test results and corrective

measures.

Search WWH ::

Custom Search