Biomedical Engineering Reference

In-Depth Information

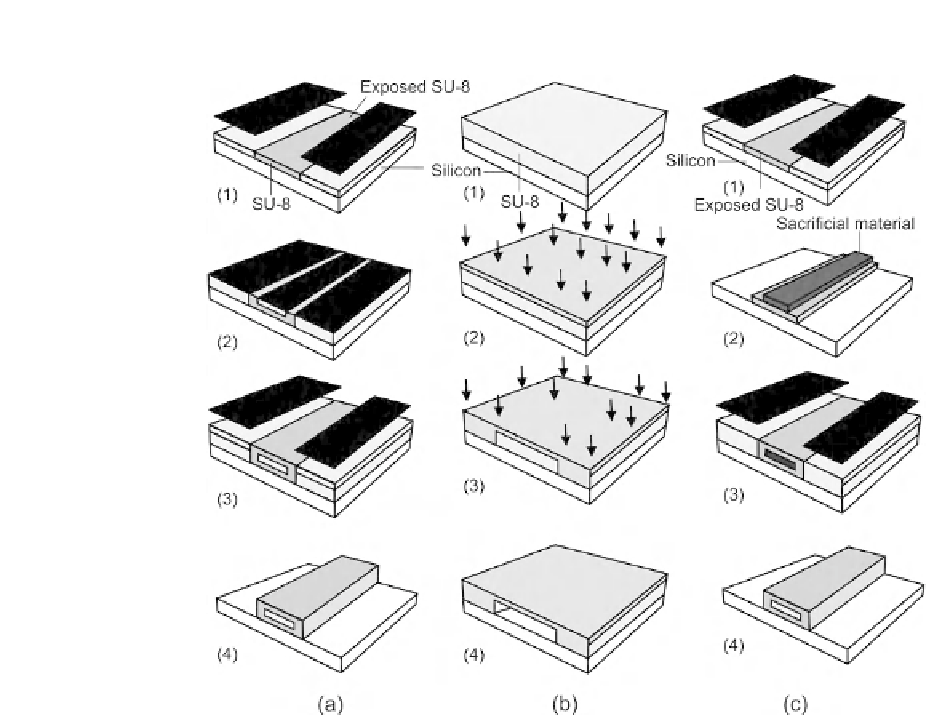

FIGURE 4.10

Fabrication of covered channels with SU-8: (a) with embedded mask (after

[62]

); (b) selective proton writing

(after

[65]

); and (c) with sacrificial layer (after

[63]

).

into the SU-8 layer and forms a thin polymerized layer (

Fig. 4.10

(b,2)). Next, the proton beam with

higher energy polymerizes the sidewalls of the channel. The high energy allows the beam to penetrate

through the SU-8 layer down to the substrate surface (

Fig. 4.10

(b,3)). In the final step, the exposed SU-

8 is developed, resulting in a covered microchannel (

Fig. 4.10

(b,4)).

Another method uses a sacrificial layer

[63,64]

to fabricate a closed SU-8 channel. The first SU-

8 layer is coated, exposed, and developed to form the bottom of the channel (

Fig. 4.10

(c1)).

Subsequently, a sacrificial structure is deposited and patterned (

Fig. 4.10

(c2)). The sacrificial

material can be thermoplastics, waxes, epoxies

[63]

, or positive photoresist

[65]

. Because of the

self-planarizing nature of an unexposed SU-8 film, the sidewalls and the channel ceiling are formed

with a single coating of a second SU-8 layer (

Fig. 4.10

(c3)). After developing the second layer, the

sacrificial material

inside the channel

is removed,

leaving a closed SU-8 microchannel

(

Fig. 4.10

(c4)).

Search WWH ::

Custom Search