Biomedical Engineering Reference

In-Depth Information

Fig. 2.11). The copolymer film is coated on a conducting substrate

(for example, ITO glass or highly doped silicon wafers with a

thermally evaporated gold layer (∼ 50 nm)), which forms one

electrode contact. A 25 μm thick polyimide foil (Kapton CR, DuPont)

with a 50 nm thermally evaporated Au layer on the reverse side

makes a convenient counterelectrode and dielectrically strong

insulating layer for the capacitor (to prevent breakdown at high

fields). Conformal contact with the polymer layer is acheived using

a thin layer (∼2 μm or more) of cross-linked poly(dimethylsiloxane)

rubber (PDMS, Sylgard 184, Dow Corning) coated on the front

side of the Kapton sheet. A constant voltage of up to 4 kV is

applied across the assembled layer while heating above the glass

transistion temperature of both components, and removed after

cooling to room temperature (where the microphase is frozen in

place in the glassy polymer matrix). The counterelectrode is peeled

away from the copolymer film, allowing subsequent etching of the

minority component.

February 8, 2010 17:21

(a)

(b)

(c)

pt counter electrode

freestanding nanowire array

au

kapton

PDMS

perforated PFS Matrix

3-

4

kV

au

v

silicon

au

replicated

nanowires

working electrode

(d)

(e)

(f)

200 nm

200 nm

200 nm

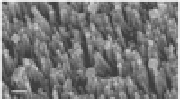

Figure

Schematic illustration of freestanding nanowire array

fabrication from electric-field-aligned, sacrificial cylinder-forming block

copolymer films. (a) Annealing of copolymer film above glass transition

temperatures in a parallel-plate capacitor geometry with applied electric

field. (b) Voids left by removal of the minority phase are electrochemically

replicated from the underlying conducting substrate. (c) The supporting

template is removed by UV ozone etching to leave a freestanding nanowire

array. (d) Tapping mode atomic force microscopy (height image) of a porous

PFS template after PLA removal. (e) Surface SEM of the electrochemically

filled template. (f) Freestanding nanowires (Cu

2.11

O/Cu mixed phase) after UV

ozone etching of PFS matrix. Reproduced from Ref. [54] by permission of

the Royal Society of Chemistry.

2

Search WWH ::

Custom Search