Information Technology Reference

In-Depth Information

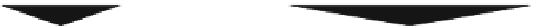

The comparison of the calculated characteristic value K

G

for the two processes

shows that the maximum tool wear appears at the outside blade (OB) of the half pro-

file blade concept. The value of K

G

at the outside blade has approximately the double

magnitude of the value of the full profile blade. The tool life of the full profile blade

was to L = 500 workpieces whereas the tool life of the half profile blades was to

L = 400 workpieces. Thus, there is a good correlation between the characteristic value

K

G

and the tool wear but there is also a good correlation between K

G

and the tool life

of the different tool concepts.

Ring Gear Manufacturing (Process 1 vs. Process 3)

Full Profile Blade

Half Profile Blade

150

75

0

OB

T

IB

OB

T

IB

OB

T

IB

3 mm

3 mm

3 mm

tool life

L = 500 workpiece

tool life outside blade

L = 400 workpiece

Fig. 13.

Comparison of different tool concepts

It can be stated that the manufacturing simulation including the calculation of the

new characteristic value K

G

allows for the first time analyzing the bevel gear cutting

process regarding the expected tool wear. Now a qualitative analysis and prediction of

tool life is possible.

5

Conclusions

Within this report the manufacturing simulation for bevel gear cutting is presented. At

first the modeling of the workpiece and the tool is realized. Under consideration of the

process kinematics the simulation can be conducted. Within the manufacturing simu-

lation a 3D penetration calculation of workpiece and tool is carried out. From the

penetrated volume the undeformed chip geometry can be calculated. With information

from this penetrated volume different characteristic value like the chip thickness can

be derived. With these values a first analysis of the cutting process regarding tool

loads and wear is possible. Unfortunately, there is often no correlation between these

singular values and the expected tool wear.

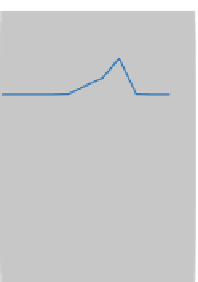

Currently a new characteristic value for the tool wear analysis is developed and

implemented in the manufacturing simulation. This new value includes the gradient of

Search WWH ::

Custom Search