Geoscience Reference

In-Depth Information

Table 14.19

Loss function, in $/ton

True grade is waste

True grade is leach ore

Estimated grade is waste

A

11

=

0

A

12

= -G/A Costs -{Leach Revenues—Proc.

Costs}

Estimated grade is leach ore

A

21

= {Waste Revenues—Proc. Costs}—G/A

Costs

A

22

=

0

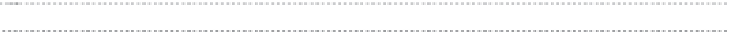

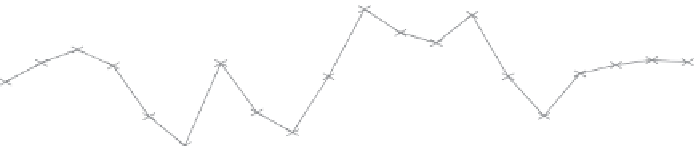

Fig. 14.59

Comparison of grade

control to Resource Model (

F

1

factors), San Cristóbal, August

1994-March 1996

*UDGH&RQWURO0HWKRGV3HUIRUPDQFH

3RO\JRQDOYV05

3RO\JRQDO*UDGH&RQWURO

05*UDGH&RQWURO

$XJ 2FW 'HF )HE $SU -XQ $XJ 2FW 'HF )HE

0RQWK

)7RQV

)*UDGH

)2XQFHV

3. The codes within each blast were visualized on screen

and a polygon is drawn to define areas of ore and waste.

This polygon was drawn manually by the grade control

technician following operational constraints.

4. The MR grade control method was based on a geological

model. This is necessary because the conditional simu-

lations do not capture sharp mineralogical or structural

transitions. The MR method is no different than any other

grade control method in that it will only produce good

results if properly controlled with in-pit mapping and a

geologic model.

5. An estimate is generally required for the tons and grade

to be recovered from each blast. At San Cristóbal the av-

erage grade of the simulations was used as the estimated

grade for each panel.

Note that the decision of where to send each block or portion

of the blast is made before any actual estimate of the grade

is obtained. The decision only depends on the relative prob-

abilities of each block of belonging to either the ore or waste

category, and the potential cost of making a mistake.

An

F

1

factor is defined to compare block model results

to grade control results. An

F

2

factor is used to compare

“loaded to heap” material to grade control predictions, as

proposed by Parker (Rossi and Parker

1993

). The

F

3

factor

(

F

3

=

F

1

*

F

2

) is used to compare tons and grade predicted by

the long-term block model (MIK) to tons and grade loaded

to heaps.

Figure

14.59

shows the

F

1

factors for the period, on a

monthly basis; the introduction of the maximum revenue

grade control method is evident. This was the only change

introduced in the operation at the time. Table

14.20

shows the

improvements achieved with the MR method. It compares

over a 13-month period the tonnages, grades, and ounces

predicted by the MIK block model to the tonnages, grades

and ounces selected by the two grade control methods.

The

F

2

factors averaged for the 13-month period in

Table

14.20

reflect tonnages actually selected and loaded to

the plant using the conditional simulation method. A 10 % un-

planned dilution in ounces in an operation with an extremely

erratic mineralization is quite reasonable. Polygonal-based

method results in dig panels that make loading and selection

in the pit much more difficult, which would make the result-

ing

F

2

factors for the polygonal method even worse. The fine

grid used by the MR method allows for an operational cut

that incorporates less dilution. Another important conclusion

is that in reality the Long-term block model (MIK) was con-

servative in tons and about unbiased in grade, and most of its

perceived shortcomings were not in fact an issue.

14.6.4

Results

From March 1995 through March 1996 the operation imple-

mented in parallel the existing polygonal and the new MR

methods, allowing for a direct comparison based on produc-

tion. The comparison demonstrated the remarkable improve-

ment achieved by the MR method.