Agriculture Reference

In-Depth Information

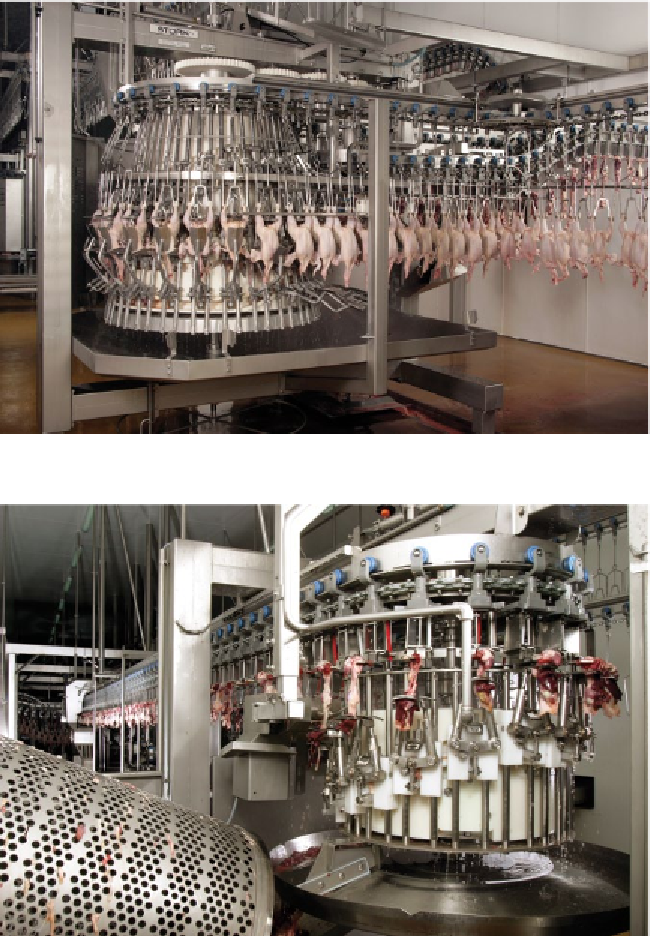

Figure 10.8

High-speed automated evisceration (Reproduced with permission from Stork Poulty Processing, Boxmeer, The Netherlands).

Figure 10.9

Liver harvesting with drum washer.

washed in chlorinated water (in the EU, the maximum

concentration of chlorine allowed in potable water is

0.5 ppm), is sorted, chilled and packed.

The eviscerated carcase is spray washed, internally and

externally (Fig. 10.10). This gives a visually clean bird and

also decreases carcase contamination. The carcase should

be washed not only after final inspection but between the

different stages involved in evisceration, as it has been

shown that by doing so the numbers of coliforms and

salmonellas on carcases are reduced because there is insuf-

ficient time for attachment to occur. A suitable carcase

washer comprises a small cabinet containing an appropri-

ate arrangement of spray nozzles (Fig. 10.11 and 10.12).

are damaged. This is not an uncommon occurrence

because the machinery used is not able to adjust for the

natural variation in the size of birds being processed.

A new type of equipment, however, holds the birds

horizontally by the head and hocks so that, when the

viscera are removed from the body cavity, they emerge

sideways. They are placed on a tray beside the bird

rather than hung with it and hence do not come into

contact with the carcase.

It is at this stage that a further inspection takes place

which will observe changes in the internal organs. After

inspection, the viscera are separated into edible and

inedible offal. The edible fraction, sometimes being