Biomedical Engineering Reference

In-Depth Information

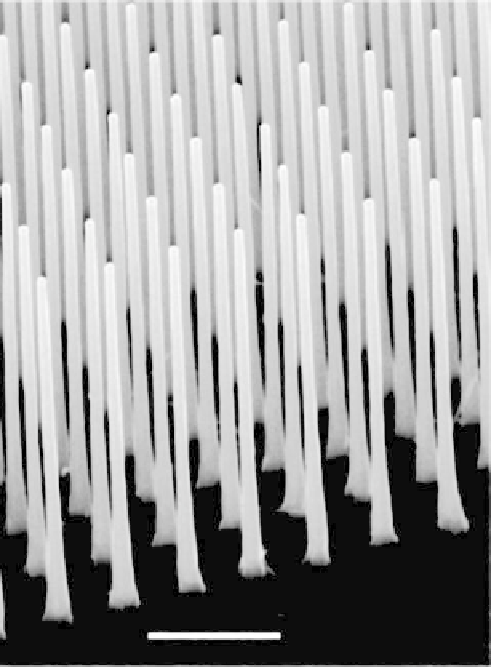

FIGURE 12.9

SEM of InP nanowires grown with MOVPE

from gold catalysts defined by electron

beam lithography. (From Samuelson, L.,

Thelander, C., Bjork, M. T., Borgstrom, M.,

Deppert, K., Dick, K.A., Hansen, A. E.,

Martensson, T., Panev, N., Persson, A. I.,

Seifert, W., Skold, N., Larsson, M. W.,

Wallenberg, L. R. (2004). Semiconductor

Nanowires for 0D and 1D Physics and

Application.

Physica E.

, 25, 313-318.)

1

µ

m

12.3.2

Synthesis of Nanowires

Synthesis methods of NWs include both vapor phase and solution techniques. Compared

with physical methods such as nanolithography and other patterning techniques,

chemical methods are seen to be more versatile and effective in the synthesis of these

NWs. The chemical synthesis includes various routes: thermal evaporation, chemical

vapor-phase deposition, metal-organic chemical vapor-phase deposition, arc discharge,

laser ablation, sol-gel, and template-based methods. The basic process of 1D nanostruc-

ture formation involves two fundamental steps: nucleation and growth. A major chal-

lenge in the synthesis of NWs is to control their size, phase purity, crystallinity, and

chemical composition. Therefore, a detailed understanding and good control of the

nucleation and growth processes at the nanometer scale is required.

12.3.2.1

Vapor Phase Growth of Nanowires

12.3.2.1.1 Vapor-Liquid-Solid Growth

The vapor-liquid-solid (VLS) mechanism was proposed by Wagner [52] in the 1960s,

when he studied the growth of millimeter-scale Si whiskers using Au as catalyst. An

advantage of the VLS method is that it can produce single-crystalline 1D nanostructures

from a rich variety of inorganic materials including elemental semiconductors (Si, Ge, and

B), III-V semiconductings (GaN, GaAs, GaP, InP, and InAs), II-VI semiconductors (ZnS,

ZnSe, CdS, and CdSe), and oxides (ZnO, MgO, and SiO

2

) [47]. A typical VLS process

involves the dissolution of gaseous reactants into nanosized liquid droplets of a catalyst