Biomedical Engineering Reference

In-Depth Information

0.6

1.2

0.5

1

0.4

0.8

0.3

0.6

0.2

0.4

0.1

0.2

0.0

0

0 0 0 0

speed (mm/min)

80

100

120

B

C

D

E

Modified Surfaces

downstroke

upstroke

I

II

90

80

70

60

50

40

30

20

10

0

0

200

400

600

800

Time (hrs)

A

B

C

D

III

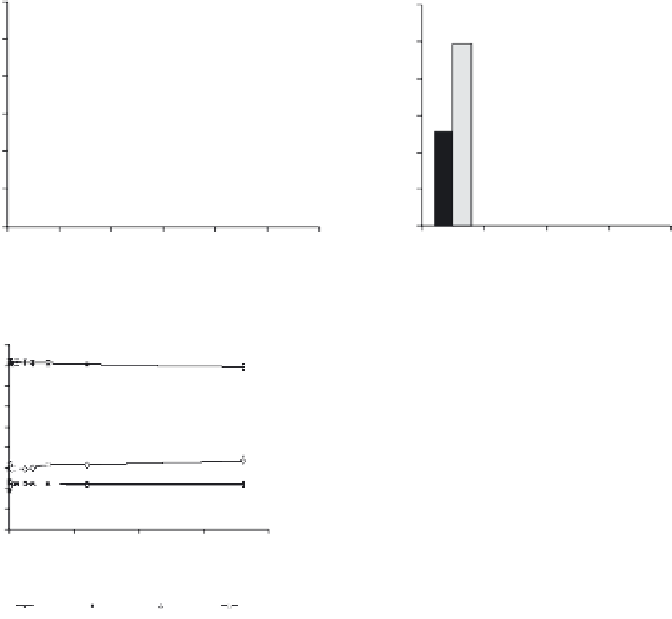

Figure 20.4.

The effect of speed on transfer ratio of the monolayer (I)

; monolayer of

(PTC : Chol) (1 : 0.7) during upstroke,

Transfer ratio of the monolayer with different composi-

tions (II)

; during downstroke and upstroke of the polymer fi lm vertically at the interface; PTC

(B), (PTC : Chol) (1 : 0.7) (C), (PTC : Chol) (1 : 0.35) (D), (PTC : Chol : GalC) (1 : 0.35 : 0.125) (E). The

surface pressure was maintained at 30 mN/m for all the monolayers during deposition.

Stabilil-

ity studies under low shear stress conditions (III)

; PMMA Bare (A), OCMC (D). PMMA modifi ed

with OCMC-AH (B), OCMC-AHP (C) (B).

for further detailed characterization. This monolayer showed a compact surface,

as evident in Figure 20.3D (1).

20.3.6 Surface Properties of Supported Thin Solid Films

The contact angle

is reduced from 85 ° to 20 ° during surface modifi cation. The

stability studies were done under low shear conditions. Figure 20.4(III) shows the

stability studies of the modifi ed surfaces, represented in terms of the change in

contact angle. The polymeric surface modifi ed with the ternary lipid layer shows

less stability as compared to the laterally stabilized surfaces. In this surface the

θ

Search WWH ::

Custom Search