Biomedical Engineering Reference

In-Depth Information

The advantage of the phase separation technique is that it is a relatively

simple technique that is not equipment intensive. In addition, a highly-porous

structure can be obtained with control over the mechanical properties of the

nanofi brous matrix and batch to batch consistency can be easily maintained [62].

However, a disadvantage of this technique can be limited control on the internal

architecture of the nanofi brous matrix [67] .

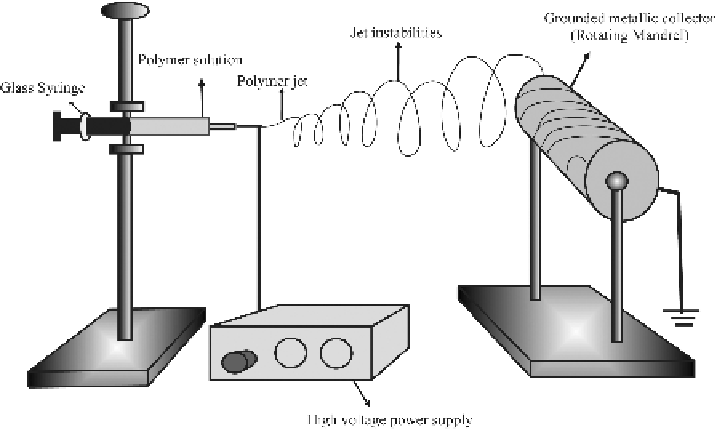

13.3.3 Electrospinning

Electrostatic spinning (electrospinning) is the synthesis of fi bers of diameter

ranging from 10 nm to 10

m or larger by drawing it from a polymer solution

under the infl uence of electrostatic forces [68,69]. The concept of electrospinning

is more than 100-years-old [70-76] and has regained the attention of researchers

for the synthesis of nanofi ber-based scaffolds for tissue engineering applications.

The apparatus for electrospinning (Figure 13.4) consists of a syringe which is

the reservoir for holding the polymer solution, capillary/needle, high voltage

power supply, grounded metallic collector (plate/mandrel), and a syringe pump

(not shown in the fi gure) that pumps the polymer at a particular rate from the

needle tip. The presence of a syringe pump is not mandatory when the syringe is

placed in a vertical confi guration, whereby the polymer solution is released from

the capillary under the infl uence of gravity. Further, the collector can either be a

grounded metallic plate that is stationary or a rotating cylinder, depending on the

requirement of a non-woven mesh or aligned fi bers, respectively.

During electrospinning, a polymer solution is taken in a glass syringe con-

nected to a metallic needle. The polymer solution by virtue of its viscosity/surface

μ

Figure 13.4.

Schematic of the electrospinning technique.

Search WWH ::

Custom Search