Biomedical Engineering Reference

In-Depth Information

tension produces a hemispherical meniscus at the tip of the capillary/needle. A

high voltage is then applied between the needle and a grounded metallic plate

that causes the induction of charges on the hemispherical droplet at the capillary

tip. Mutual charge repulsion (coulombic repulsion) on the meniscus of the

polymer solution induces a force that is initially balanced by the surface tension

of the polymer. An increases in the voltage causes higher surface charges on the

polymeric droplet and its elongation leading to the formation of a cone like struc-

ture called the Taylor cone [77]. With further increase in the voltage above a

particular threshold, the repulsive forces overcome the surface tension forces and

a jet ensues from the tip of the Taylor cone. The jet travels straight for a short

distance and then undergoes bending instabilities that lead the jet to traverse a

spiral path. During the course of movement of the jet to the collector plate, it

thins due to solvent evaporation and stretching caused by bending instabilities

[78]. Higher charges on the jet leads to increased elongation forces and hence

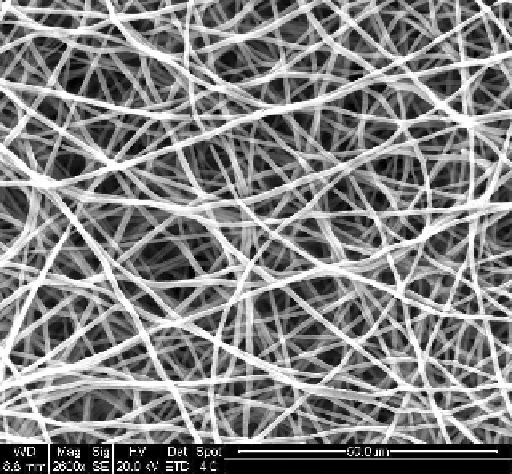

reduced fi ber diameter. The solidifi ed polymeric nanofi bers are deposited on the

grounded metal plate in the form of a non-woven mesh (Figure 13.5).

Electrospinning has been extended from the phenomenon of electrostatic

spraying (electrospraying). In electrospraying, charge is provided to a conducting

liquid that splits mid-air, resulting in the formation of spray of fi ne particles fol-

lowing jet formation; hence, the process is termed as electrospraying [70,71].

When high molecular weight polymers are used instead of low molecular weight

substance, the process leads to the formation of continuous fi bers, and hence the

Figure 13.5.

Scanning Electron Micrograph of PLGA nanofi bers (non-woven mesh) synthe-

sized by the electrospinning technique. (Unpublished data from the laboratory).

Search WWH ::

Custom Search