Biomedical Engineering Reference

In-Depth Information

(a)

500

μ

m

(b)

20

μ

m

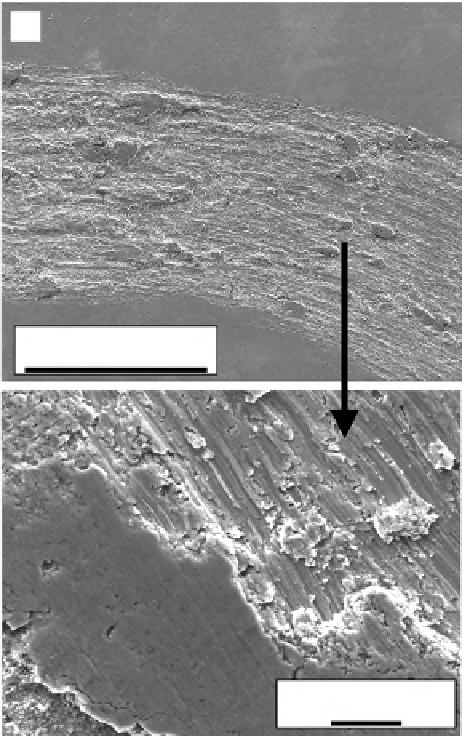

Figure 9.29.

(a) Lower magnifi cation and (b) higher magnifi cation secondary SEM images

of TNZT + 2B wear tracks after friction studies using SS440 counterface balls. [Sonia Samuel

et al.

Wear Resistance of Laser Deposited Boride Reinforced Ti

-

Nb

-

Zr

-

Ta Alloy

Composites for

Orthopedic Implants

(to appear in Mater. Sci. Eng. C, 2007)]

surface morphology has undergone a plastic shear deformation mechanism

usually associated with less wear volume removal. This is evident by examining

some of the larger surface depressions with plastic fl ow process. These results

show that much lower friction coeffi cient and improved wear resistance can

be obtained by using a softer counterface material in case of TNZT + 2B as-

synthesized state, when compared to Ti-6Al-4V ELI alloys.

9.3.4.4 Summary of Ti-Nb-Zr-Ta + TiB Composites.

The summary of

Ti - Nb - Zr - Ta + TiB Composites is as follows:

Search WWH ::

Custom Search