Biomedical Engineering Reference

In-Depth Information

pull-out, third body abrasive wear observed with the harder Si

3

N

4

counterface.

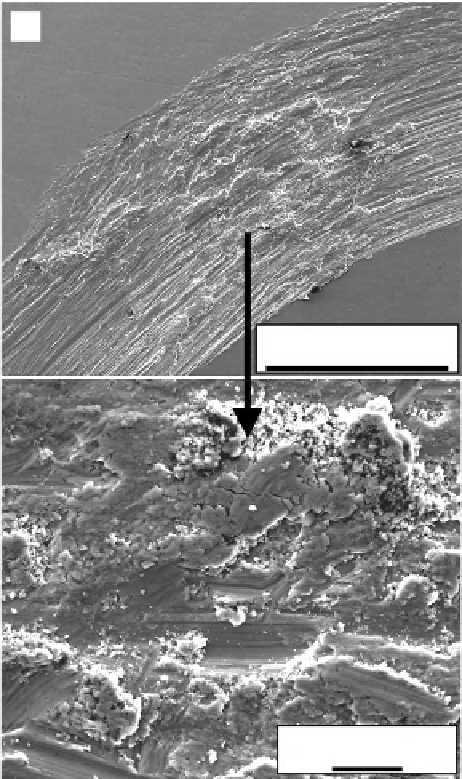

The corresponding SEM images of the wear tracks shown in Figures 9.28 and

9.29 for Ti - 6Al - 4V ELI and TNZT + 2B, respectively, corroborate the friction

behavior.

The wear track morphology of Ti-6Al-4V ELI in Figure 9.28 shows more

extensive plastic deformation, microplowing and cutting, all typical processes

associated with an abrasive wear mechanism. Conversely, the TNZT + 2B wear

track shown in Figure 9.29 exhibits less severity in wear. It is apparent that the

(a)

500

μ

m

(b)

20

μ

m

Figure 9.28.

(a) Lower magnifi cation and (b) higher magnifi cation secondary SEM images

of Ti-6Al-4V ELI wear tracks after friction studies using SS440 counterface balls. [Sonia Samuel

et al.

Wear Resistance of Laser Deposited Boride Reinforced Ti

-

Nb

-

Zr

-

Ta Alloy

Composites for

Orthopedic Implants

(to appear in Mater. Sci. Eng. C, 2007)]

Search WWH ::

Custom Search