Biomedical Engineering Reference

In-Depth Information

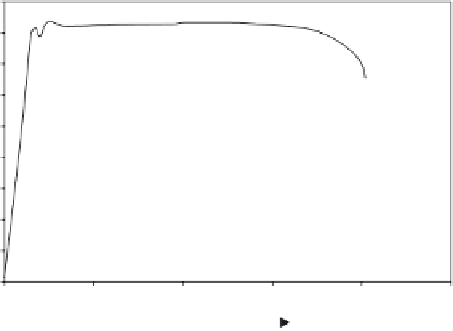

900

800

700

600

500

400

300

200

100

0

= 118 ksi = 813.58 MPa

= 121 ksi = 834.26 MPa

= 55 GPa

= 19%

0.2% YS

UTS

Modulus

Elongation

0

5

10

15

20

25

Strain (%)

Figure 9.6.

An engineering stress-strain curve for the LENS™ deposited TNZT tensile sample.

[Rajarshi Banerjee et al.

Laser Deposited Ti-Nb-Zr-Ta Orthopedic Alloys

(J. Bio. Mater. Res., 78A

(2), 2006), 298.]

it should be noted that these nanometer-scale precipitation products have been

reported in other conventionally-processed TNZT alloys which exhibited a

similar modulus but a substantially lower strength [30,31]. In the stress-strain plot

shown in Figure 9.6, there is a dip in the plot just after yielding (initiation of

plastic deformation). This dip in the stress can be attributed to the classic yield

point phenomena, which is often observed in case of metals and alloys exhibiting

a

bcc

crystal structure [32] .

9.3.3.3 Deformation Mechanisms.

In order to investigate the reason for

the enhanced strength in greater detail, SEM-OM and TEM studies have been

carried out on the LENS™ deposited samples post tensile testing. A cross-section

OM map of a tensile specimen, recorded from the gauge section, is shown in

Figure 9.7a. The viewing direction is parallel to the tensile axis. This OM map has

been pseudo-colored based on the crystallographic orientations (Euler angles)

of the different regions of the sample. Regions exhibiting the same crystallo-

graphic orientation are depicted in the same color. The map shown in Figure 9.7a

is a direct image of the grains in this sample. The average grain size is

m as

determined by the TSL OIM Analysis software based on ASTM standards for

grain size measurement. In addition to the grain size and morphology, the actual

crystallographic orientations of the different grains can be determined as shown

in the pole fi gures for the

∼

50

μ

β

phase in Figure 9.7b. This pole fi gure corresponds to

grains in a region of 1 mm

×

1 mm of the gage section. The {001}

β

, {011}

β

, {111}

β

,

and, {112}

pole fi gures are shown. These pole fi gures indicate that there is a pref-

erential alignment of the {001} poles for a substantial number of the

β

β

grains

nearly perpendicular to the substrate, or parallel to the tensile axis.

Thus, most of the

axis along the

viewing direction that is parallel to the tensile axis. This preferential alignment of

β

grains seen in Figure 9.7a have a

<

001

>

Search WWH ::

Custom Search