Biomedical Engineering Reference

In-Depth Information

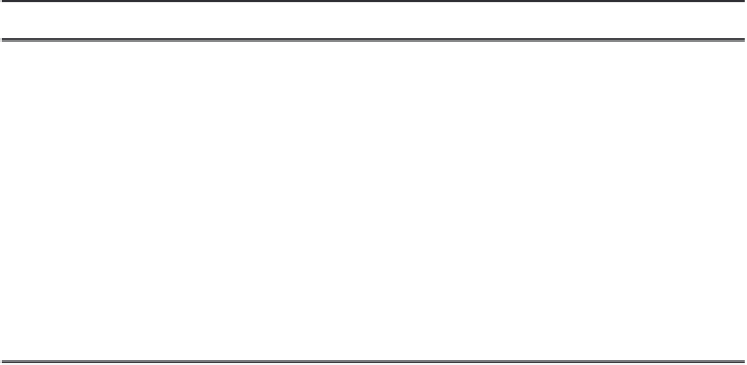

TABLE 8.5. Fabrication Techniques of Various Micro/Nano Devices

Device

Fabrication techniques

Microneedles, Micropumps/Microvalves,

Implantable microchip

Micromachining techniques adopted from

microelectronics industry

Liposomes

High pressure homogenization, microemulsion

method and high speed stirring

Nanofi bers

Electrospinning, drawing, self assembly, phase

separation and template synthesis

Dendrimes

Convergent synthesis and divergent synthesis

Nanotubes and fullerenes

Chemical vapor deposition, electric arc

discharge and laser ablation

Nanogels

Emulsion polymerization and crosslinking

reaction of preformed polymer fragments

Nanocrystals

Wet comminution, precipitation, disintegration

and milling

of biomaterial surfaces (chemistry and topography) will develop simultaneously,

thereby leading to improved biomedical devices.

8.5 CONCLUSION AND FUTURE DIRECTIONS

Newly developed biomaterials have revolutionized the fi eld of biomedical devices

in the past few years. Hence, the selection, manufacturing and processing of bio-

materials has gained increased importance in the recent past. After the selection

of an appropriate biomaterial, their processing and fabrication techniques are

the parameters that can signifi cantly infl uence the performance/function in the

intended fi nal application. These processing techniques can be fairly diverse for

biomaterials due to the diversity in type of biomaterials—metals, ceramics, poly-

mers, composites. However, for all of these classes of biomaterials, conventional

methods of processing can have limitations for use in biomedical applications.

Hence, newer techniques that offer advantages such as desired mechanical and

chemical properties, precise control on device dimensions, and improved repro-

ducibility have been developed.

On a parallel front, the modifi cation of implant surfaces for improved inte-

gration with neighboring tissue has witnessed signifi cant progress. A variety of

methods have been developed to modify surface chemistry and topography at

both the macro as well as the micro/nanometer scale. Newer fabrication tech-

niques at the micro/nanometer scale have also led to improved devices such as

advanced drug delivery systems, scaffolds for tissue engineering applications, and

biosensors. Nanotechnology borrowed from the electronics industry has been

used extensively for fabrication of micro/nanometer scale structures like micro

pumps, valves, implantable chips (Bio-MEMS/NEMS), self-regulated drug deliv-

ery devices, and micro needles. In the future, it is expected that the processing

Search WWH ::

Custom Search