Biomedical Engineering Reference

In-Depth Information

For the purpose of this example, consider the lighting in a semi-manual inspec-

tion booth, where inspectors look for particulates and defects in vials of a product.

On the basis of this assessment, the system, the inspection booth, and the

lighting in the booth would be deemed critical according to affirmative answers

to #5 and #6. Utilities that support the booth, such as electrical power, would

be deemed as having indirect impact. So the booth and the lighting should be

qualified. The decision to qualify the electrical power source would depend on the

amount of variation in the power source, the effect on lighting intensity that such

a variation might have, and the effect of intensity variation on product quality or

the ability of the inspector to see and reject defective units.

7.3.8 To What Extent Would it be Qualified?

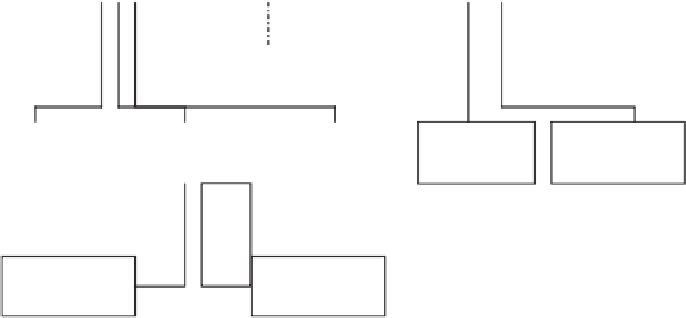

Once a system or component has been classified according to level of impact, a

decision should be taken as to how to assure the correct function of that system.

This can be done by asking the question—what could go wrong and what would

cause such a situation or failure? Tools such as fault tree analysis, partially

illustrated in Figure 7.5, and fishbone analysis, partially illustrated in Figure 7.6,

can be helpful in identifying those process steps or conditions that pose a risk to

product quality. These tools are designed to break the process into smaller steps

where risk can more effectively be addressed and reduced.

Inability to

effectively

inspect units

Lighting

failure

Human

error

Unit

vibration

Shadowing

effects

Broken or

missing

bulbs

Control

system

malfunction

Variation in

power supply

Improper

set up

Excessive line

speed

Inadequate

wiring

Corroded

connections

Figure 7.5

Fault tree analysis example.

Search WWH ::

Custom Search