Biomedical Engineering Reference

In-Depth Information

Preliminary Risk Assessment - Where is the risk?

(HU)MAN

MACHINES

MEASUREMENT

SPC for CPPs

Training

Line speed

Set up

Lighting

measurement

Vision

Lighting

intensity

Speed

measurement

qualification

Safe & effective

meets customer's

expectations,

particulate free

vials

corrugated

controls

Physical

Realign with

strategic goals

Particulates

Process

Review and

Plan

Nozzle strikes

Provide

resources

Analytical

Glass shards

MATERIALS

MANAGEMENT

METHODS

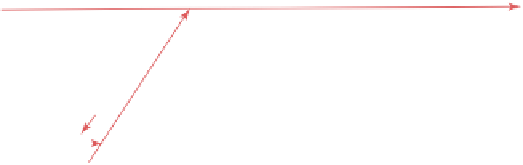

Figure 7.6

Ishikawa Fishbone analysis example. (

See insert for color representation of

the figure

.)

7.3.9 Criticality Analysis

Another method of impact assessment might ask questions related to: How impor-

tant is the function of the equipment or system to the quality of the product? Let

us look at this from the perspective of the light example.

1. What

is the impact on product quality if

this process step—visual

inspection—fails?

2. How important is the system or component—lighting—to the success of

the process step?

3. How robust is the process? How much variance can the process take and

still be effective—what are the operating parameters?

4. How effective or reliable are the control systems in place to control varia-

tion and prevent failure?

5. How effective are the ways to detect a failure before it adversely affects

the quality of the product or patient safety?

6. What is the control strategy or risk mitigation/risk reduction strategy for

assuring that process results remain in specification?

For the purpose of this exercise—one could use a simple HIGH, MEDIUM,

and LOW rating system. HIGH means very important, severe, definitely could

happen. LOW means not very important, not of much concern, doubtful it would

happen; MEDIUM is everything in between. Question (6) requires a more exten-

sive answer.

Search WWH ::

Custom Search