Biomedical Engineering Reference

In-Depth Information

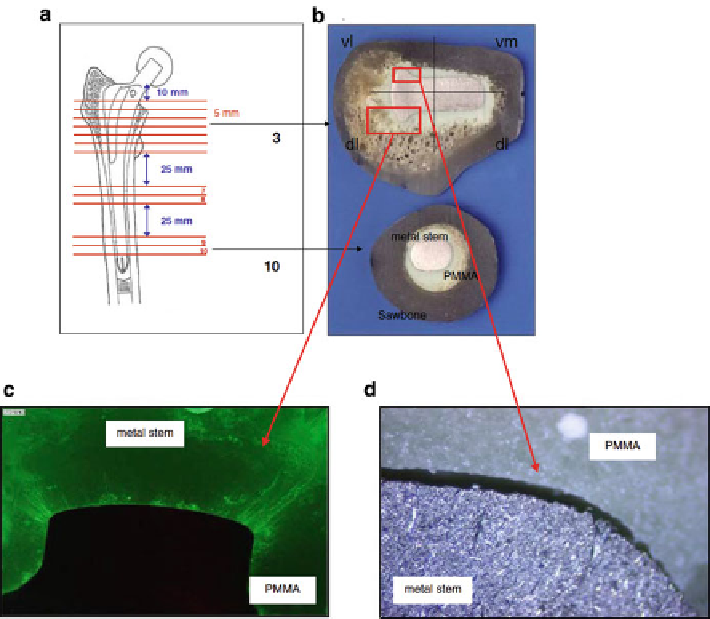

Fig. 1.8

(

a

) Schematic of implant in a femur. (

b

) Representative slices of the implanted stem

surrounded by bone cement. (

c

) Cement mantle cracks generated from “sharp-edge” corners. (

d

)

Debonding along the metal-bone cement interface (adapted, with permission, from [

13

])

Consider, for example, the attachment of stems to the femur for total hip

arthroplasty. Stress shielding can result in bone loss if stresses are poorly distributed

along the bone-metal interface. In the case of a noncemented stem, this problem

can be alleviated if the fixation is implemented along the entire length of the stem

surface [

11

]. The use of hydroxyapatite coatings may enhance bone ingrowth and

reduce bone resorption, without a detrimental effect on the stress distribution. One

of the solutions proposed to alleviate the problem of attaching metal to bone

employed a graded interface between the metal and bone materials as is exemplified

by cemented hips (Fig.

1.8

). The cement (polymethylmethacrylate) is first applied

to the hip to avoid a direct linking between the bone cement and metal of the

artificial hip. The tendency of the metal-cement interface to debond is alleviated

through the use of a silane-coupling coating of metal that enhances the hydrolytic

stability [

12

]. The metal-to-cement bond can further be improved using an addi-

tional silica oxide interlayer that adheres to the oxide on the surface of metal [

13

].

In the experiments reported in this study, femur stems covered with a silica/silane

interlayer coating were cemented into artificial femur bones and subject to standard

Search WWH ::

Custom Search