Biomedical Engineering Reference

In-Depth Information

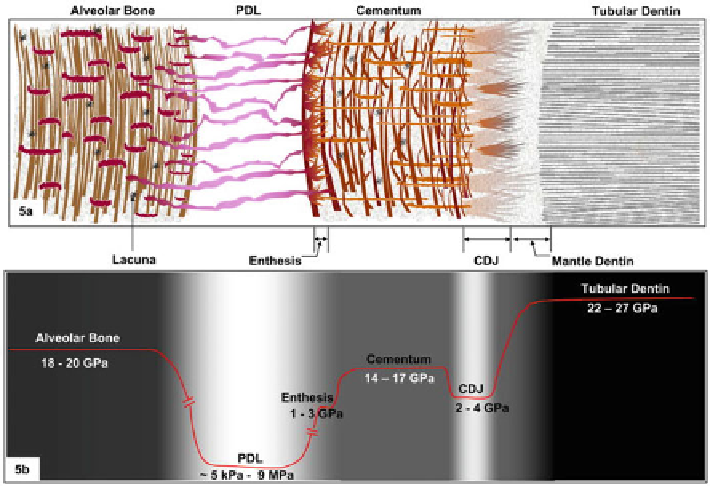

Fig. 1.7

Schematics of the tissues and interfaces responsible for tooth attachment. (

a

) Structure

and (

b

) variation of the modulus of elasticity, reflecting the presence of graded regions between

bone, PDL, cementum, and root dentin (adapted, with permission, from [

9

])

Notably, the surface structure, in particular the surface roughness, and the surface

chemistry of oral implants influence their anchoring in jaw bones. In one study, the

metal-to-bone interface between an implant surface and a jawwas modified by sand-

blasting the metal component with different particles [

10

]. The surface modification

of the titanium implant was produced by blasting it with particles of Al

2

O

3

or of

bioceramics; these treatments resulted in improvements in attachment. This

illustrates that an artificially developed roughness on the implant surface may benefit

attachments for tooth implants. Nevertheless, caution should be exercised using this

approach, since local damage may be introduced in the material during the blasting

process. Additionally, the mechanisms by which this improvement is attained are

not understood. The presence of local roughness may serve as a source of micro-

scopic stress concentrations; a macroscopic crack may originate from one of these

local areas. Alternatively, the roughness might serve as a cue for living cells within

the jaw to produce material more conducive to an effective metal-to-bone interface.

1.2.2.2 Metal-to-Bone Orthopedic Interfaces

Metal-to-bone interfaces in orthopedic total joint implants have been extensively

investigated. A mismatch in the stiffness along the interface can cause both pain

and eventual loosening or failure, requiring replacement of the artificial joint. A

second issue that can lead to negative outcomes is the biocompatibility of the metal.

Search WWH ::

Custom Search