Biomedical Engineering Reference

In-Depth Information

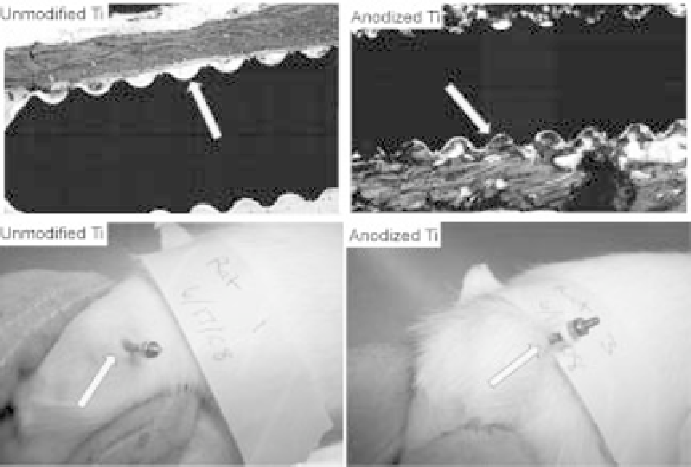

9.7 In vivo comparison of unmodified titanium and anodized titanium. (Arrows

point out the comparison of bone growth (top) and inflammatory responses

(bone) between unmodified and anodized titanium. Adapted from Puckett et

al. [47].)

parameters of anodized titanium, like oxide thickness, the pore size distribution,

the porosity and the crystallinity of the surface oxides may be factors that

influence tissue±material interactions. Similar experiments were also conducted

with sheep and rats in which anodized titanium screws or rods were inserted for

4 to 12 weeks. Again, as shown in Fig. 9.7, histological results showed that

anodized nanotubular titanium implants have excellent cytocompatibility

properties and an ability to quickly grow bone next to the implant [48±50].

Moreover, no infection or inflammatory responses were observed around the

anodized nanotubular titanium screws (Fig. 9.7). It is also important to note that

anodization is a quick (less than an hour) and inexpensive technique to modify

the surfaces of titanium-based implants to improve bone cell functions required

for improving orthopedic applications.

As a comparison of all three methods mentioned here for nanostructured

metal modification, wet chemistry etching is the easiest approach. It requires

little equipment and can react with a large amount of metal samples at the same

time. However, the disadvantage of this method is that it is an uncontrollable

process creating uneven surface morphologies. In contrast, the Temescal

electron beam evaporation technique requires a high vacuum chamber and an

extensive energy source supply. In addition, the evaporation and condensation of

metal atoms usually take a little bit longer than chemical etching. However,

Temescal electron beam evaporation can provide even or patterned nano-surface