Biomedical Engineering Reference

In-Depth Information

evaporate freely throughout the vacuum chamber. The atoms and molecules in

the vapor flow then condense onto the substrate surface located at the top of the

chamber, creating a coating that masks the original surface. It was found that

compared with conventional nano-smooth titanium and nano-featured titanium,

osteoblasts adhered and aligned on such nanostructured metal features. Such

observations confirmed the hypothesis that nano-featured titanium can improve

early osteoblast functions (morphology and adhesion), promising for promoting

longer-term functions (such as calcium deposition), criteria necessary to

improve orthopedic implant efficacy [35±37].

Another promising technique that has recently emerged to create nano-

features on titanium is anodization. Anodization is an electrochemical method

also known as anodic oxidation and is widely used as a surface modification

technique for metals to produce protective oxidative layers [38]. Such anodiza-

tion processes usually operate in an acidic solution. Anodization will result in

the formation of an oxide layer on the anode surface. At the same time, the acid

will etch the oxidative layer to cause the initial formation of pores at the weak

points on the titanium surface due to localized dissolution. Then, voids will form

in these inter-pore regions by field-enhanced oxidation/dissolution [39±42].

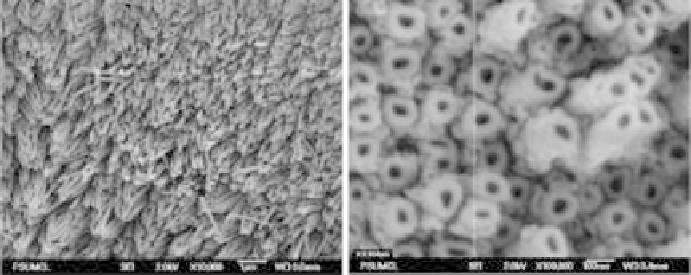

After the anodization of titanium, self-ordered nanotubular surface morpholo-

gies may be observed, as shown in Fig. 9.6.

An in vitro study provided evidence of enhanced calcium deposition by

osteoblasts cultured on anodized titanium with nanotube-like structures

compared with unanodized titanium and titanium anodized to process nano-

particulate structures [43, 44]. A number of in vivo studies have also demon-

strated the promising future of anodized titanium for orthopedic applications.

For example, anodized titanium screws were inserted into rabbit tibia and

allowed to penetrate one cortical layer. After 6 weeks, histology stains showed

bone tissue formation on the nanostructured titanium implant surfaces that had

an oxide thickness of more than 600 nm [45, 46]. Results indicated that the

9.6 SEM images of anodized titanium foil samples. (Adapted from Ruan et al.

[39].)