Biomedical Engineering Reference

In-Depth Information

Figure 10.5

AFM images of the injection-molded PEEK: (a) unmodified, relatively smooth surface; (b) 600 s modified,

showing little change in the surface roughness; (c) 1800 s modified PEEK showing pits created as a result of the longer

treatment time. The change in topography observed is due to the “etch effect” of prolonged exposure to oxygen

plasma; this pitting could potentially provide anchorage points for osteoblast cell adhesion. (d) Micro-rough medical

grade titanium showing a much greater surface roughness than that observed on the PEEK surfaces (10 mm

scale bar).

a period of 26 months, the surface chemistry and

wettability of our oxygen plasma-modified PEEK

surfaces have been evaluated and shown to be stable.

Oxygen plasma treatment is known to affect surface

topography; we therefore evaluated the modified and

unmodified PEEK surfaces by atomic force micros-

copy (AFM).

AFM analysis of the untreated PEEK, presented in

Fig. 10.5

a, showed the residual striations from the

injection mold, where the maximum peak to trough

distance observed was under 300 nm, and the stria-

tions were relatively irregular. Following 600 s of

plasma treatment, as presented in

Fig. 10.5

b, the

surfaces were still quite similar to the surfaces of the

unmodified PEEK, although the peaks of the striations

were slightly less sharp. Minor changes to the surface

roughness were observed on all the surfaces modified

for less than 1200 s (data not shown); however, those

surfaces modified for longer had a very apparent

change in the topography, where the etch effect of the

plasma treatment was obvious, clearly showing the

striations to be less prominent, leading to a more

uniformly rough surface. After 1800 s of exposure to

oxygen plasma, the etching of the surface was very

apparent, shown in

Fig. 10.5

c, where the surface

topography has clearly changed, and the original

striations were hardly visible; these pits were also

confirmed by scanning electron microscopy (SEM).

The surface roughness of all the surfaces showed that

all the PEEK surfaces were relatively smooth in

comparison to standard microrough commercially

pure titanium (Ti; ISO 5832/2; Synthes, CH). The

etching effect of the plasma treatment did not signif-

icantly change the surface roughness of the modified

PEEK surfaces, although the surfaces from the longer

treatment times do have a slightly higher average

roughness. Having confirmed the increase in surface

oxygen, change in topography and increase in surface

energy, the surfaces were evaluated for their cyto-

compatibility with human primary osteoblast-like

(HOB) cells evaluating cellular attachment, prolifer-

ation, morphology, and characteristic behavior over

28 days in vitro culture.

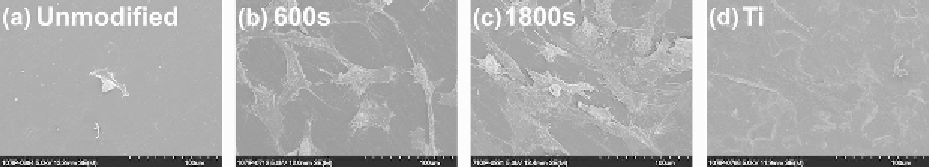

Figure 10.6

shows the HOB

cell adhesion 1 day postplating.

Assessing the cell density and thereby prolifera-

tion on the various sample surfaces allows the effect

Figure 10.6

Scanning electron micrographs showing HOB cell attachment 1 day postplating to the (a) unmodified,

(b) 600 s, (c) 1800 s modified PEEK, and (d) microrough medical grade titanium (Ti). There was much greater cell

adhesion and spreading to the modified PEEK and Ti surfaces (b, c, d) in comparison with unmodified PEEK (a), where

the cells appear to be lifting off.