Biomedical Engineering Reference

In-Depth Information

interface

. The overall mechanical behavior of

a composite is thus governed by the properties of

the individual constituents and the interfaces

between them. In the case of PEEK, the polymer is

typically designed as the matrix of the composite

and constitutes most of the volume in the polymer

composite.

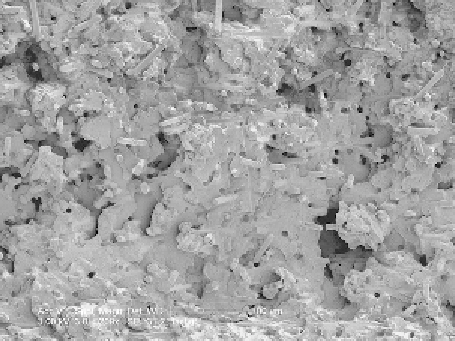

As already alluded to previously in this chapter,

carbon and glass fillers were among the first rein-

forcement additives for PEEK to increase its strength

and stiffness

[29]

. PEEK forms a strong interface

with carbon fibers, effectively transferring stress

between the fibers and the polymer matrix (

Fig. 1.8

).

The strength and modulus of carbon fiber-reinforced

PEEK (CFR-PEEK) depend on the size, length, and

orientation of the fibers. CFR-PEEK biomaterials are

currently used in implants for spine fusion and joint

replacement.

PEEK biomaterials are also engineered for the

biomedical, as well as their biomechanical, func-

tion. PEEK may be mixed with radiopacifiers, such

as barium sulfate, to improve visualization and

contrast in medical imaging. Image contrast grades

of PEEK are commercially available for implant

applications and are currently used in spinal

implants.

Researchers are also investigating the combination

of PEEK and bioactive fillers, such as hydroxyapa-

tite, to enhance bone growth around implants.

Although structural and image contrast formulations

of PEEK are relatively well understood, bioactive

PEEK composites represent a novel field in bioma-

terials under active research and development. In

Chapter 3 of this

Handbook

, we explore PEEK

composites more thoroughly.

1.7 Overview of This Handbook

The primary goal of this

Handbook

is to provide

a comprehensive, state-of-the-art assessment of

PEEK and PEEK composites as a family of bioma-

terials. In recent years, advances in the processing

and biomaterials applications of PEEK have been

progressing steadily. Previously, much of the

research on PEEK implants has been fragmented in

the materials science, composites, biomaterials, and

application-specific literature. Consequently, we

have also sought to synthesize data from the mate-

rials science, polymers engineering, biomaterials,

and clinical literature to make this information more

readily available and to hopefully facilitate new

research in this field.

This

Handbook

is organized in three main

sections. The first part of this

Handbook

provides the

reader with a foundation in PEEK structure, proper-

ties, and behavior. As background for this mono-

graph, we have provided in this introductory chapter

an initial summary of polyaromatic ketones as the

basis for understanding the chemical, physical, and

mechanical properties of this family of polymeric

biomaterials. Chapter 2 summarizes the techniques

for processing PEEK and fabricating PEEK compo-

nents, and Chapter 3 further covers the field of PEEK

composites. Chapters 4

e

6 describe the structure and

morphology,

fatigue and fracture behavior, and

chemical

and

radiation

stability

of

PEEK

biomaterials.

The second part of this

Handbook

summarizes the

biocompatibility of PEEK and recent developments

in the engineering of PEEK biocomposites. Chapter 7

provides an overview of studies in the literature

analyzing the biocompatibility of PEEK. In Chapter

8, the interaction between PEEK and microbiological

organisms is summarized. Surface modification of

PEEK can be achieved using bioactive coatings

(Chapter 9) or by plasma treatment (Chapter 10).

Chapter 11 covers advances in the field of hydroxy-

apatite-PEEK biocomposites, and in Chapter 12, we

describe efforts to introduce porosity into PEEK

biomaterials for creating tissue scaffolds.

The third part of this

Handbook

provides an

overview of current applications of PEEK implants.

We provide an overview of the clinical applications

Figure 1.8

Freeze fracture surface of CFR-PEEK

(PEEK OPTIMA LT130). Image courtesy of Ryan Baxter,

Ph.D., Drexel University.