Biomedical Engineering Reference

In-Depth Information

Cells

Solvent casting and particulate leaching

Sub-pores

Sub pores

Pores

Pores

Gas foaming

Emulsification and phase separation

Fiber diameter

Electrospinning

Casting

Tube diameter

Nanopattern

Lithography

Solid free-form fabrication

Pores

Pores

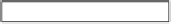

FIGURE 2.6

SFF fabrication techniques compared to other scaffold fabrication technologies and the dimen-

sions of the generated scaffolds.

where the laser beam strikes the surface of the bath, resulting in the creation of a fi rst solid plastic

layer at and just below the surface. The solid layer is then lowered into the bath, and the laser-

generated polymerization process is repeated for the generation of the next layer, and so on, until

a plurality of superimposed layers forming the desired scaffold architecture is obtained. The most

recently created layer in each case is always lowered to a position for the creation of the next layer

slightly below the surface of the liquid bath. Once the scaffold is complete, the platform rises out of

the vat and the excess resin is drained. The scaffold is then removed from the platform, washed of

excess resin, and then placed in an UV oven for a fi nal curing.

For industrial applications, the photopolymer resins are mixtures of simple low-molecular-weight

monomers capable of forming solid long-chain polymers by chain reactions when activated by radi-

ant energy within specifi c wavelength range. The commercial materials used by SL equipment are

epoxy- or acrylate-based resins that offer strong, durable, and accurate parts or models. However,

these materials cannot be used as scaffold materials due to the lack of biocompatibility and biodegrad-

ability. Hence, the limited availability of photopolymerizable biomaterials is a major constraint for the

use of the SL technique in the design and fabrication of scaffolds for tissue engineering applications.

However, biocompatible acrylic, anhydride, and polyethylene oxide (PEO)-based polymers may be

explored in future research, as they are already typically at the clinical research stage as curable bio-

adhesives or injectable materials. A variation in laser intensity or traversal speed may be employed

to alter the cross-link or polymer density within a layer so that the properties of the material can be

varied from position to position within the scaffold. This variation enables the fabrication of so-called

biphasic or triphasic matrix systems. Microstereolithography (MSL) in particular is thought to offer a

great potential for the production of 3-D polymeric structures with micrometer resolution.

2.3.1.2

Selective Laser Sintering

Selective laser sintering (SLS) also uses a focused laser beam, but with the intention of sintering

areas of a loosely compacted powder. In this method, a thin layer of powder is spread evenly onto

a fl at surface with a roller mechanism. The powder is then raster-scanned with a high-power laser

beam. The powder material that is struck by the laser beam is fused, while the other areas of powder

remain dissociated. Successive layers of powder are deposited and raster-scanned, one on top of one

another, until an entire part is complete. Each layer is sintered deeply enough to bond it to the pre-

ceding layer. Wiria et al. have used SLS to produce biocompatible PCL/TCP scaffolds from starting

powders; the scaffold demonstrated good osteoblast-like cell responses such as attachment levels

and proliferation.

23

However, SLS has inherent material constraints for scaffold fabrication and is