Biomedical Engineering Reference

In-Depth Information

20.4.2 I

NJECTABLE

B

ULKING

M

ATERIALS

Injectable bulking agents constitute a feasible and attractive procedure to replace conventional

surgery for a number of pathological conditions. Bulking agents have been used for many years

to successfully treat patients with urinary incontinence [24]. As a result of this success, a small

number of pilot studies have recently reported the use of bulking materials for the treatment of fecal

incontinence in patients with weak but intact internal anal sphincter.

20.4.2.1 Polymer Microspheres

The fi rst reported injectable bulking biomaterial used in the treatment of partial fecal incontinence

was a paste of polytetrafl uoroethylene (Tefl on [Du Pont de Nemours & Company, Inc., Wilmington,

Delaware] or Polytef), one of the most widely used biomaterials in medicine [25]. Polytef paste is

a mixture of polytetrafl uoroethylene, glycerin, and polysorbide fabricated as microspheres with

sizes ranging from 4 to 100 µm, with 90% in the 4-40 µm range. Despite the reported therapeutic

effi cacy of Polytef, polytetrafl uoroethylene-based materials have many drawbacks that limit their

usefulness for sphincter augmentation. Moreover, polytetrafl uoroethylene spheres have been found

to migrate from the implantation site to distant organs and because they are nonbiodegradable are

thought to have triggered granulomatous foreign body reactions, fever, and pneumonitis [26,27].

The problem of detecting transmigration of bulking biomaterials is exacerbated by materials, such

as poly(methyl methacrylate), polytetrafl uoroethylene, and silicone rubbers being radiolucent, that

is, invisible with x-ray imaging. Because of the potentially serious clinical implications of this type

of material, an ideal long-lasting injectable biomaterial is sought as a bulking agent for incontinence

that is nonantigenic, volume-stable, and nonmigratory.

Microspheres remain an attractive choice for bulking materials due to their relative ease of

delivery and ability to conform to the shape of the implantation site. A number of fabrication tech-

niques for producing microspheres have been developed and reported to date, but the choice of the

fabrication technique depends on the nature of the polymer, the intended use, and the duration of

the therapy. Whichever technique is used, the following criteria should be achievable: (i) the yield

of microspheres within the desired size range should be high, (ii) the quality of microspheres should

be reproducible, and (iii) microspheres produced should be free fl owing and should not aggregate

or adhere to one another.

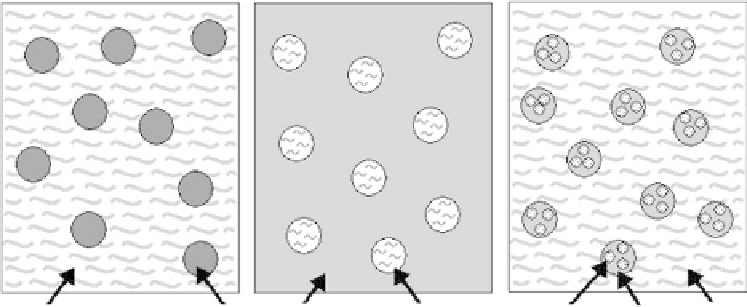

Emulsion solvent diffusion techniques are frequently used to produce microspheres and can be

classifi ed as either “in-water” methods or “in-oil” methods (Figure 20.3). The oil-in-water single

Oil-in-water

Water-in-oil

Water-in-oil-in-water

2

1

Water

Water

Oil

Oil

Water

Water

Oil

FIGURE 20.3

Schematic illustration of single and double emulsion processes for the fabrication of

microspheres.