Biomedical Engineering Reference

In-Depth Information

[170]. When a rutile titanium oxide layer is formed on the surface of a matrix, the blood compat-

ibility can be improved signifi cantly [166,170]. Several techniques to prepare titanium dioxide fi lms

have been reported, such as thermal oxidation [170], anodic oxidation [171], magnetron sputtering

[172-175], cathodic vacuum arc deposition [176-178], and ion beam enhanced deposition (IBED)

[166]. Titanium oxide fi lms used in artifi cial heart valves have also been synthesized using PIIID

technology in City University of Hong Kong and Southwest Jiaotong University, Chengdu, China

[35,133,179].

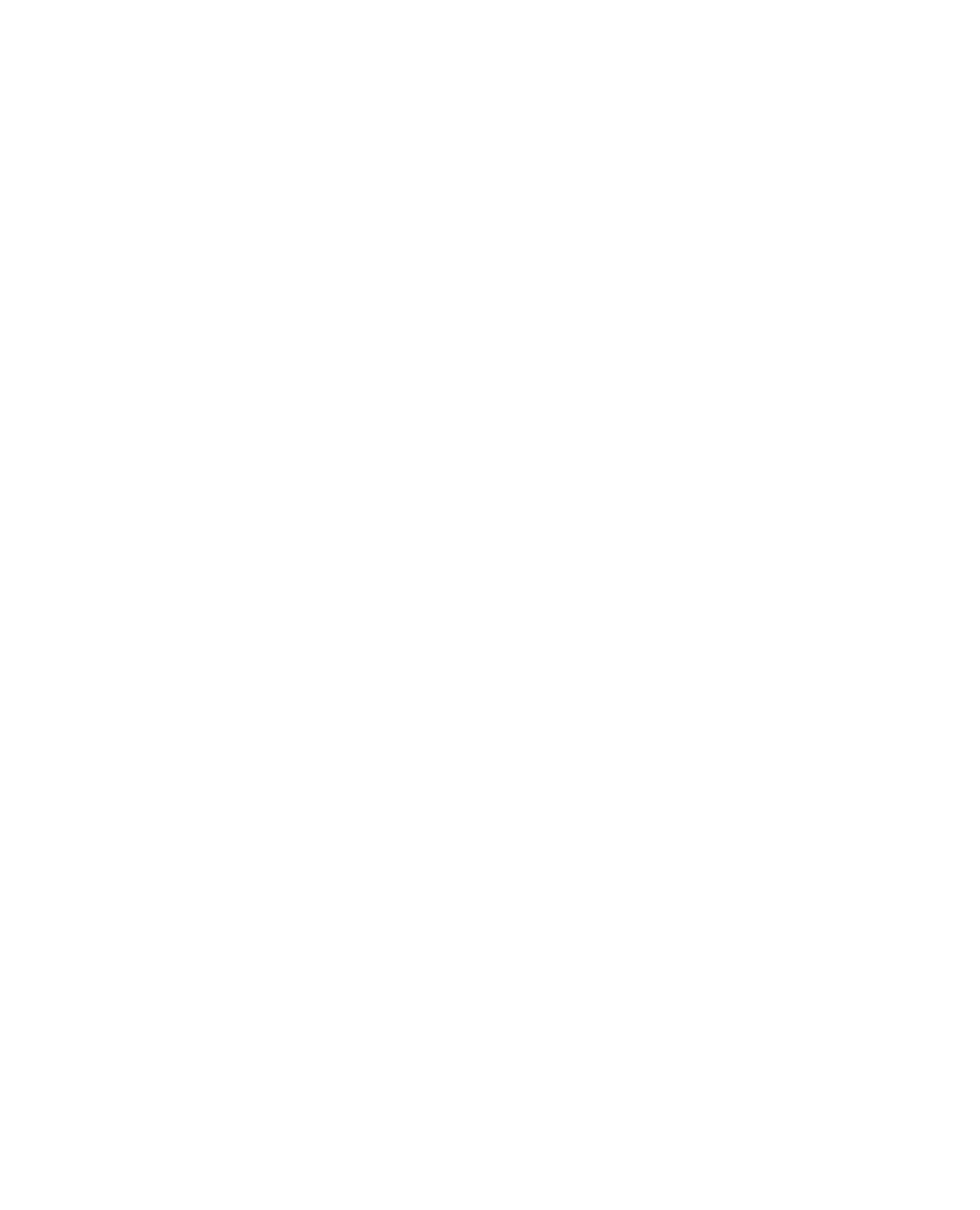

The PIII system used in this work is schematically shown in Figure 19.46. A Ti cathode

14 mm in diameter was mounted on the metal vacuum arc plasma source. An oxygen plasma was

sustained by RF in the vacuum chamber and at the same time, a titanium plasma was generated

in the metal arc source and diffused into the vacuum chamber via a magnetic duct to eliminate

deleterious macroparticles. The voltage on the sample was

50 V DC and the deposition time

was 60 min. The deposition rate varied from 0.1 to 0.15 nm/s depending on the oxygen gas fl ow

rate. To increase the adhesion between the fi lm and silicon (100) substrate, a

-

3 kV pulse voltage

(10 kHz, 5 μs) was applied to the sample during the fi rst 10 min. Table 19.8 lists the instrumental

-

RF plasma chamber

O inlet

Ar inlet

Titanium source

Cathodic arc source

RF antenna

Ti

+

Sample stage

Substrate

Negative pulsed bias

To vacuum pump

FIGURE 19.46

Schematic diagram of the PIII system applied to prepare the Ti-O thin fi lm.

TABLE 19.8

Instrumental Parameters for Samples #1 to #5

Samples

#1

#2

#3

#4

#5

Vacuum arc

Metal plasma

Source

Pulse repetition rate (Hz)

65

Pulse width (ms)

1

Arc current (A)

180

Oxygen gas fl ow (sccm)

3.1

5

7

10

15

Oxygen partial pressure (

×

10

-2

Pa)

0.63

0.93

1.2

1.7

2.7

RF power (W)

600