Biomedical Engineering Reference

In-Depth Information

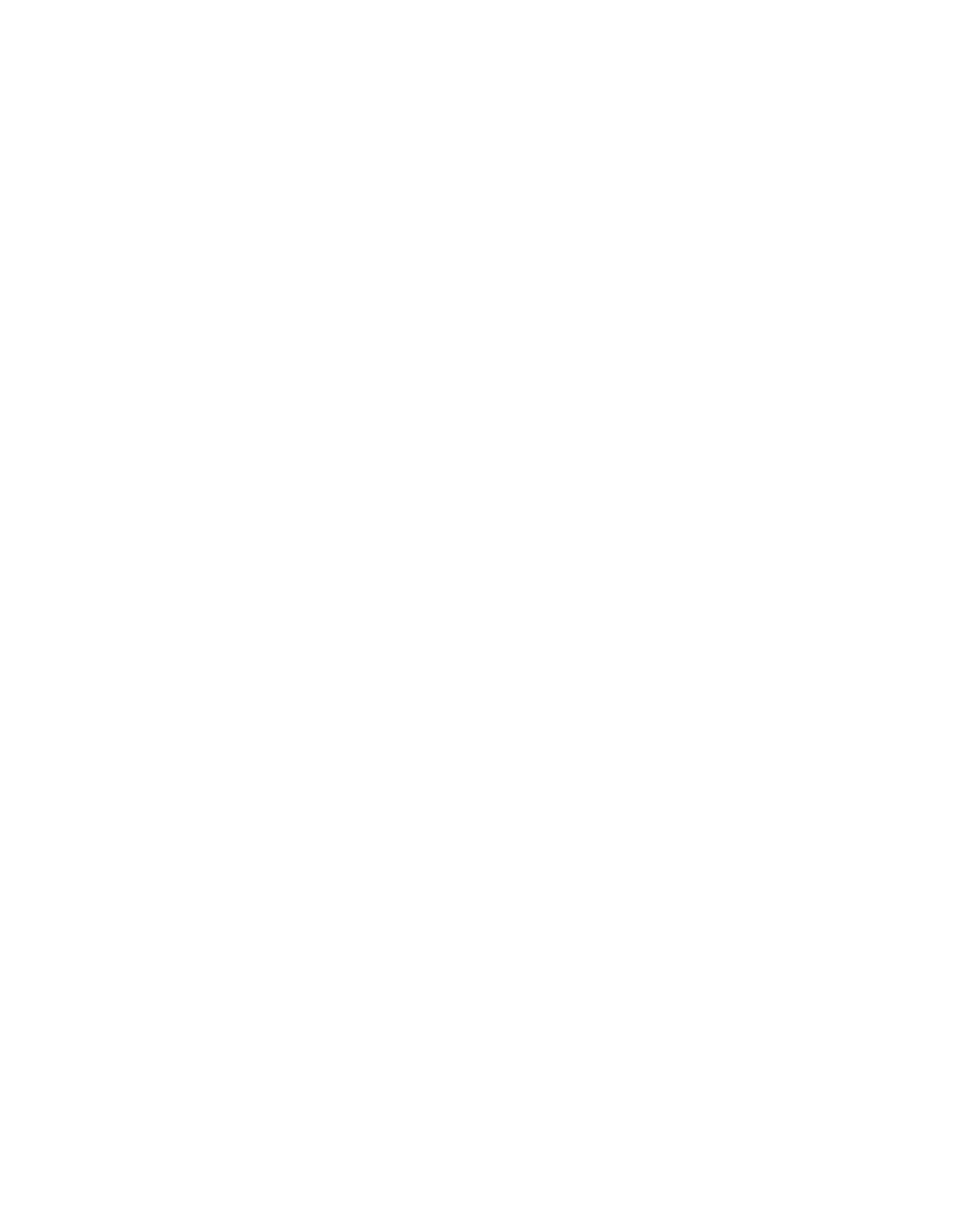

TABLE 19.6

Interfacial Energies between Materials and Plasma Proteins

Ca-DLC

CaP-DLC

P-DLC

LTIC

Biological

Substances

γ

s

p

/

γ

s

d

γ

s

p

/

γ

s

d

γ

sp

γ

s

p

/

γ

s

d

γ

s

p

/

γ

s

d

γ

sp

γ

sp

γ

sp

Fibrinogen

6.7

0.04

45.4

4.62

6.5

0.02

16.8

12.2

Albumin

11.2

0.11

35.8

6.31

10.7

0.08

11.8

46.6

Source

:

Kwok, S.C.H. et al.,

Diam. Relat. Mater.,

15, 893, 2006. With permission.

TABLE 19.7

Contact Angle (

θ

w

) and Interfacial Energy (

γ

sw

) between Different

Materials (Samples) and Water

γ

sw

(nJ/cm

2

)

Materials

θ

w

(

°

)

Ca-DLC

87.2

6.2

CaP-DLC

51

57.6

P-DLC

49

5.1

LTIC

74.9

24.2

Source

:

Kwok, S.C.H. et al.,

Diam. Relat. Mater.

, 15, 893, 2006. With permission.

The interfacial energies (

γ

sp

) between plasma proteins and samples are shown in Table 19.6.

Ca-DLC (0.11) and P-DLC (0.08) have lower values of

γ

sp

p

/

γ

sp

d

for albumin (

γ

sp

p

and

γ

sp

d

represent

the polar and dispersive components of the interfacial energy between proteins and materials) than

CaP-DLC and LTIC, suggesting stronger adhesion of albumin. The

γ

sp

p

/

γ

sp

d

ratio for fi brinogen is

also small, but the total interfacial energy,

γ

sp

, is less than that of albumin, which means that less

conformational changes occur. The results suggest that these surface energies are the primary

factors for the good compatibility observed on Ca-DLC and P-DLC in the platelet adhesion test.

Table 19.7 shows the results of the contact angles and calculated interfacial energies (

γ

sw

) between

water and the fi lms. Ca-DLC and P-DLC have the lowest values of interfacial energy (

γ

sw

=

6.2

and 5.1, respectively) with water (medium), indicating that both fi lms have closer interfacial ten-

sion (1-3 nJ/cm

2

) with the cell medium than CaP-DLC and LTIC. Hence, the platelet results are

consistent with the calculated surface energy.

19.5.2 T

I

-O T

HIN

F

ILM

Titanium oxide is widely used in optical and electrical applications because of its high refractive

index and dielectric constant. It is also very attractive as a biocompatible protective coating on

medical implants, where a protective surface layer of TiO

2

increases the wear resistance and hard-

ness considerably. Dissolution of Ti metal ions from the rutile phase is one order of magnitude lower

than that from anatase, and so rutile is the preferred phase with respect to biomedical applications