Biomedical Engineering Reference

In-Depth Information

with defi nable micro- and nanostructures provides an opportunity to develop enhanced biological

and medical devices, which may lead to enhanced performance of devices such as vascular grafts,

tissue scaffolds, and templates for guided tissue regeneration. There are two differences between the

CES and the FFESS processes. Firstly, the FFESS relied on a charge-injection electrode to charge

the solution surface and resulted in reproducible charging and stable axisymmetric electrospraying.

Secondly, at high voltages the charge injection was dominated by fi eld injection because of the

sharp electrode, and thus generated fi ner particles and fi bers.

11.2.8.2.3

Native Biomaterials

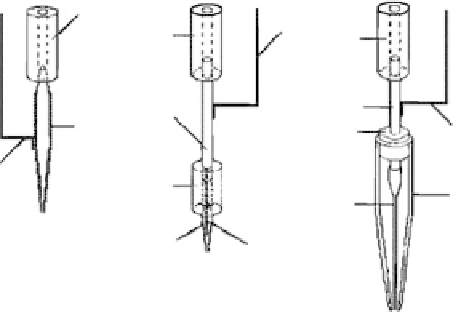

The manufacturing of protein and other biomolecule biomaterial fi lms onto an electrode surface is a

necessary step in the fabrication of enzyme electrodes and other types of biosensors for biomedical

application. Morozov and Morozova were the fi rst to prepare functionally active protein fi lms

using electrospraying [77]. A schematic diagram of the setup for depositing protein is shown in

Figure 11.27. They used a solution prepared by dissolving a commercial dry powder of alkaline

phosphates in water. In the experiment, three different designs of the capillaries for electrospraying

were studied. The fi rst design, as shown in Figure 11.27a, was a glass capillary coated with a silver

layer on the external surface of a glass capillary. A conductive wire that is in contact with the coated

capillary was connected with a high-voltage power supply. In the second design, as shown in Figure

11.27b, the metal electrode was not exposed to a gas phase in order to reduce the risk of corona

discharge at high voltage, which was a glass capillary with an inner electrode. In the third version

of the capillary design, as shown in Figure 11.27c, a liquid bridge between the electrode and the

solution was introduced to avoid any contact of the metal electrode with the protein solution. The

external surface of the stainless steel tube was used as an electrode exposed to the interior of the

large external glass capillary, whereas the internal thin plastic capillary was used to supply protein

solution. The setup for depositing protein materials is shown in Figure 11.28. The experimental

results showed that the functional activity of alkaline phosphates could completely survive the

electrospraying process. Electrospraying neither destroyed the compact native structure of alkaline

phosphates protein molecules nor irreversibly inactivated them. It is defi nitely a feasible technique

to fabricate biologically specifi c fi lm materials for biosensors, libraries, and diagnostic assays.

(a)

(b)

(c)

1

3

1

1

4

4

2

1

3

3

1

5

7

5

6

FIGURE 11.27

Types of capillaries used for electrospraying: (a) capillary with external electrode, (b)

capillary with internal electrode, and (c) capillary with a liquid bridge. (1) Plastic tubing, (2) glass capillary

coated with the silver layer, (3) contact wire, (4) stainless steel tube, (5) glass capillary, (6) internal tung-

sten or stainless steel electrode, and (7) plastic capillary. (Reprinted from Morozov, V.N. and Morozova,

T.Y.,

Anal. Chem.

, 71, 1415, 1999. © American Chemical Society. With permission.)