Geology Reference

In-Depth Information

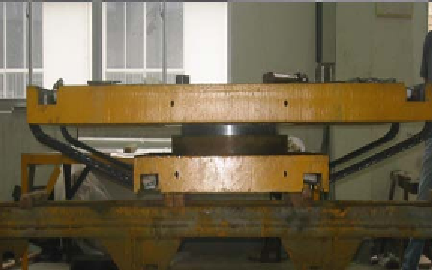

Figure 16. Prototype bearing

the fixed pier is PS1. For the new cable sliding

friction aseismic bearing used only on the fixed

pier PS1 in the bridge, the vertical load bearing

capacity is 35000 kN, the friction coefficient is

0.02 and the shear strength of the shear bolt is 3500

kN. The seismic responses are evaluated by using

an artificial synthetic ground motion (Figure 19),

whose excess probability is 3% in 100 years (Cao,

2009). The artificial synthetic ground motion is

applied in the longitudinal direction at the base of

the piles and abutments, while the vertical ground

motion is two thirds of it.

Since the stiffness of the cables is very impor-

tant for the new bearing, it is necessary to analyze

the seismic demand variations of the bridge along

with the stiffness of the cables. Parametric analy-

ses are conducted and the results are shown in

Figure 20, in which the left vertical coordinate

indicates the seismic shear force at the bottom of

pier PS1 and the right one indicates the maximum

longitudinal seismic displacement of the deck

end. It can be seen that the seismic displacements

of the deck end decrease rapidly, while the seismic

shear forces at the bottom of pier PS1 do not in-

crease too much, as the cable stiffness increases.

Yet the shear forces increases a little and the deck

displacement changes slightly when the cable

stiffness gradually increases from 1×10

5

to 3×10

5

kN/m.

bearing. The results also show that the experi-

mental hysteretic curves agree with the numerical

ones well and the displacement restraining capac-

ity of the cables is significant.

Application Study

From the above theoretical assumptions and

analyses, the new cable sliding friction aseismic

bearing seems sound and acceptable. After some

conformation improvements in order to be fit for

the requirements and convenience of manufac-

tures, the modified shop-manufactured bearing

shown in Figure 17 is applied in a girder-arch

composite bridge with spans of three 210 m, whose

finite element model is shown in Figure 18 and

Figure 17. Modified shop-manufactured bearing

Search WWH ::

Custom Search