Geology Reference

In-Depth Information

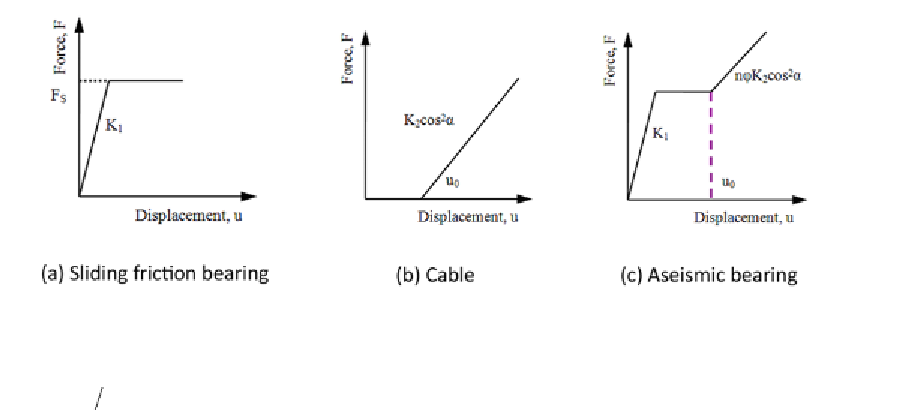

Figure 15. Stiffness models

The axial stiffness of a cable member is defined

as

K

cables,

u

0

denotes the design free displacement

when the bearing is in normal service load and

α

is the angle between the longitudinal direction

of the cable when engages at a lateral displace-

ment of

u

0

and the direction of the horizontal

relative displacement of the friction bearing. So

combined with the characteristics of the fric-

tional bearing and the cables, the integral stiffness

model of the cable sliding friction aseismic bear-

ing can be shown in Figure 15c, where

n

is the

number of cables and

ϕ

is a coefficient that

represents the equivalent linearization of cable

stiffness under severe earthquakes.

Depending on pseudo-static cyclic loading

experiments and finite element analyses for a

prototype cable sliding friction aseismic bearing

(Figure 16) where the maximum vertical load is

5000 kN, the actual values of the bearing's char-

acteristics, such as the static and dynamic friction

coefficients of the bearing's sliding surface, the

cable stiffness, the experimental hysteretic curves

of the bearing and the corresponding skeleton

curves, can be obtained (Cao, 2009; Yuan, Cao,

Cheung, Wang & Rong, 2010). The experimental

results show that the static and dynamic friction

coefficients decrease as the vertical load increas-

es. Through the experiments and calculations, the

coefficient

ϕ

is suggested to be 0.373 for its ap-

plication in theoretical analysis models of the new

2

1

=

, where

E

is the elastic modulus of

the cables,

A

1

is the cable section area and

L

is

the cable length.

EA L

2. Shear strength of the bolt

Considering the requirements under service

loads, the horizontal shear resisting capacity of

the fixed-type pot bearing should not be less than

10% of the vertical load bearing capacity (Cao,

2009). Depending on the performance objects,

the shear bolt should be out of service during

severe earthquakes. So it is suggested that the

shear strength of the bolt be within 10% to 15%

of its vertical load capacity.

3. Integral stiffness of the bearing

The lateral stiffness of a frictional bearing can

be simplified as an ideal bilinear model as shown

in Figure 15a, where

K

1

denotes the elastic stiff-

ness of the bearing and

F

s

denotes the critical

friction force which is calculated as

F

s

=

µ

where

µ

is the friction coefficient and

N

is the vertical

force on the bearing. The cables can be regarded

as completely elastic material since they should

not yield, whose load-displacement curve is shown

in Figure 15b, where

K

2

is the stiffness of the

N

Search WWH ::

Custom Search