Biomedical Engineering Reference

In-Depth Information

Interestingly, no vertebrate has the capacity to digest cellulose enzymatically. Herbivores

subsist largely on cellulose, not because they can digest it themselves, but because their

digestive tracks contain microbes that produce cellulose-hydrolyzing cellulases; various

cellulase types are also synthesized by fungi. When compared to starch, cellulose is relatively

resistant to biodegradation. Each cellulose molecule is an unbranched polymer of 10

3

-10

6

d-glucose units (Flieger

et al

., 2003 ).

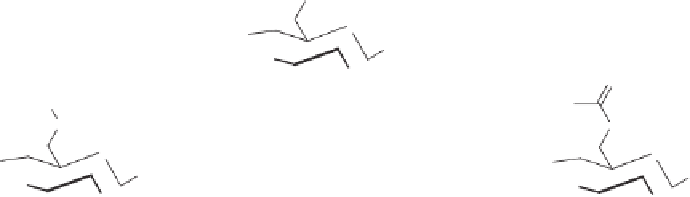

Although paper has been known for more than 2000 years, the sensitivity of the

mechanical properties towards water limits the use of cellulose as a material in many

applications. Moreover, cellulose cannot be thermally processed into plastics because of its

hydrogen-bonded structure. However, microfibrils with diameters ranging from 2 to 10 nm

and lengths reaching several micrometers can be isolated from native cellulose fibers

through a combination of chemical and mechanical methods. The viscose process has been

known for more than 100 years and although it is far from being environmentally friendly

(Figure 11.3) it dominates other methods for isolating cellulose fibers. Cellulose processed

in this way finds applications from textile fibers to technical fibers for cords of high

performance tires (rayon) or for film (cellophane) production, which is suitable for food

packaging (Guerra

et al

., 2005). An environmentally friendly method, the Lyocell process,

was developed in the 1980s as an alternative to the viscose process, in which

N-methylmorpholine-N-oxide (NMMO) monohydrate is used as a more convenient solvent

system, resulting in a process practically free from emissions since solvent recovery is

almost complete (Klemm

et al

., 2005 ).

Their mechanical properties, with a Young's modulus of

140 GPa, close to that of

Kevlar, make cellulose fibers ideally suited as reinforcing elements in composite materials

(Gandini, 2008). Moreover, cellulose ultrathin films are also of great interest for their

extreme wetting behavior with aqueous systems and for being extremely stable against

oxidation and thermal degradation (Schaub

et al

., 1993 ; Kontturi

et al

., 2006 ). These features

make cellulose interesting for two distinct types of materials, cellulose composites and

thermoplastically processable cellulose derivatives.

∼

Viscose

Blends or

composites

Cellulose

Fibers & Films

+ CS

2

+ NaOH

Biodegradable

or

non-degradable

polymer

+ NMMO

Lyocell

OH

O

O

O

HO

OH

O

O

2

N

OO

O

O

+ HNO

3

+ H

2

SO

4

O

H

3

C

O

O

CH

3

O

O

O

O

HO

HO

OH

OH

Nitrocellulose

Celluloseacetate

Figure 11.3

Modification possibilities of cellulose.

Search WWH ::

Custom Search