Biomedical Engineering Reference

In-Depth Information

and starch domains. From tensile testing, the stress at break and modulus were observed to

increase significantly with the starch content and -NCO/-OH molar ratio. Much research

has also been carried out to enhance the fire resistance of PU by the incorporation of

phosphorus, halogens, or nitrogen-containing compounds, or by the use of rigid molecules

either as polyol or as isocyanate (Donnelly

et al

., 1991 ).

Because of their low immunogenic potential, potential bioactive behavior, capability of

interacting with the host's tissue, chemical versatility, and almost unlimited source, starch-

based polymers are considered to be ideal materials for tissue engineering (Cunha

et al

.,

2004). Different degradable porous architectures have thus been developed using polymers

based on blends of corn starch with poly(ethylene-co-vinyl alcohol)(SEVA-C, Novamont,

Italy) and cellulose acetate (SCA, Novamont, Italy)(Gomes

et al

., 2001 ). These materials

present a non-cytotoxic behavior and are under consideration for a wide range of biomedical

applications, such as scaffolds for bone-tissue engineering (Salgado

et al

., 2004 ).

Another future application of starch might be in the field of electro-active polymers or

polymer electrolytes. Although starch is an insulator and its proton mobility is low, upon

doping with MX (NaCl, NaI, LiCl, LiI), it exhibits conductance between 10

-5

and 10

-6

S/

cm (compared to 10

-9

-10

-11

S/cm for starch which contains 30% water) (Finkenstadt,

2005). Recently, Khiar and Arof (2010) studied an electrolyte based on starch and different

amounts of ammonium nitrate. The study revealed that the conductivity was increased

from 6.28 × 10

-10

to 2.83 × 10

-5

upon addition of 25% ammonium nitrate at room temperature.

One of the most recent and interesting application possibilities of starch is shape-memory

materials. Non-modified starch has been shown to present very efficient shape-memory

capabilities, with a recovery ratio of R

r

> 90% for a fixed deformation of 200%, which was

permanently shaped by extrusion, and this shape was stabilized below T

g

. A second shape

was gained

via

thermo-molding above T

g

and shape recovery was triggered by water sorption

at 20 °C. The study stimulates the use of starch as environmentally friendly smart material

(Véchambre

et al

., 2010 ).

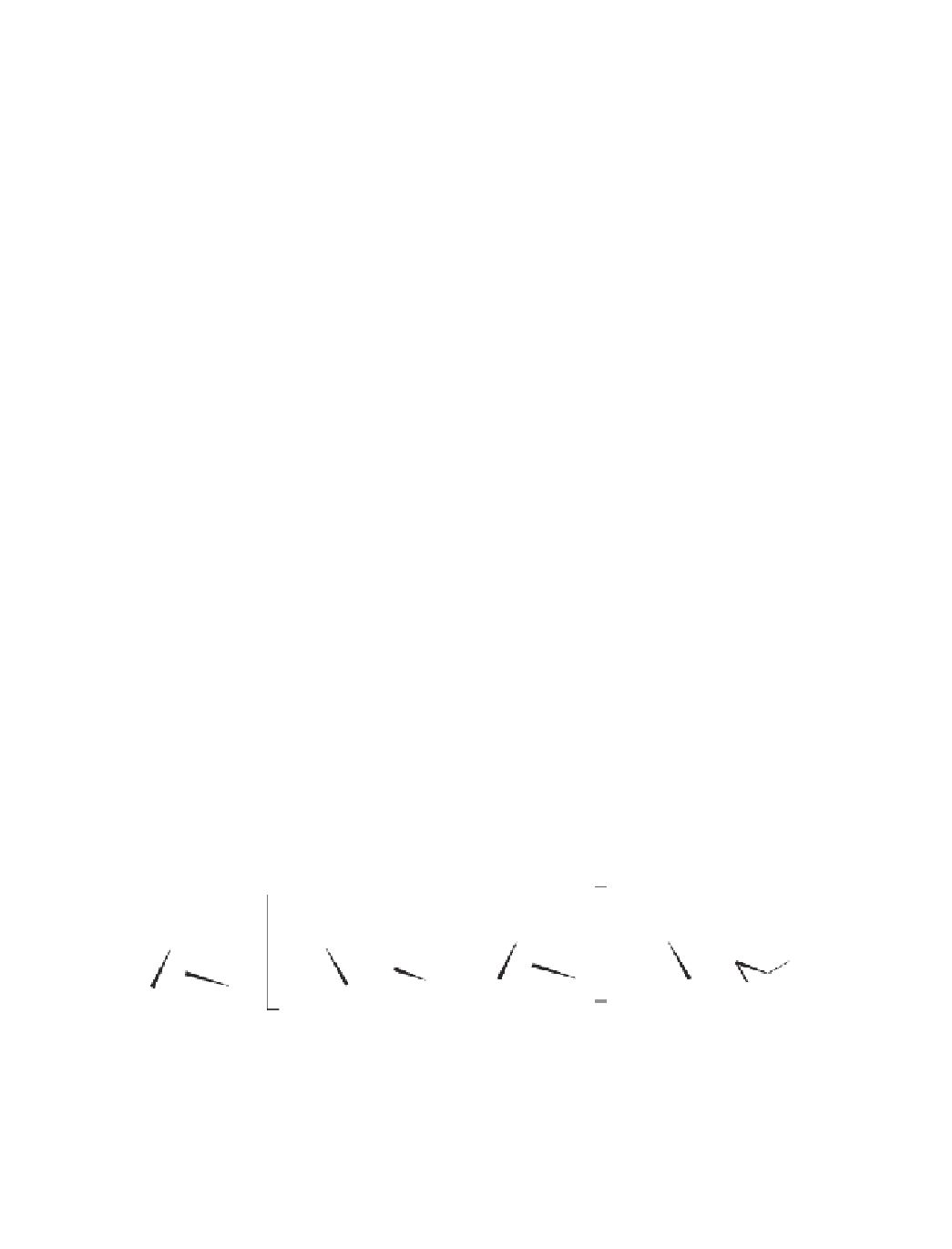

11.2.2 Polymers from cellulose

Cellulose, next to chitin, is the most abundant biopolymer on earth. It is the major constituent

of plant cell walls and more than half of the organic carbon on earth is fixed in cellulose. It

is composed of unbranched, linear chains of d-glucose molecules linked through 1,4-

β

-d

glycosidic bonds (Figure 11.2).

Glucose

unit

OH

OH

OH

OH

O

O

O

O

H

O

HO

OH

O

H

O

H

O

O

HO

O

OH

OH

n

OH

OH

Cellobiose repeat unit

Cellulose

Figure 11.2

Chemical structure of cellulose.

Search WWH ::

Custom Search