Biomedical Engineering Reference

In-Depth Information

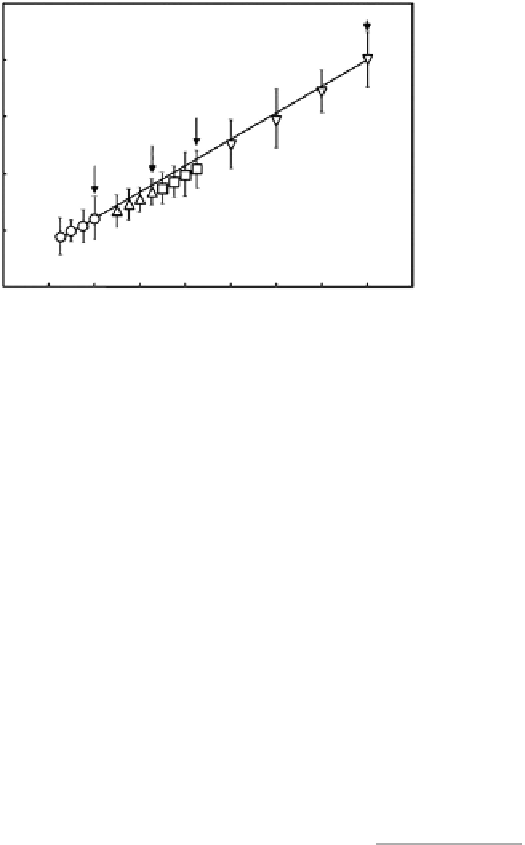

250

200 nm

200

103

150

83

60

100

50

0

0

1

2 3 4

Solution concentration (wt.-%)

5

6

7

8

9

Figure 9.5

Relationship between the concentrations of the prespun chitosan/TFA solutions and the mean diameters of the

electrospun chitosan fibers. Numbers with arrows indicate the mean fiber diameter in the optimized spinning

condition, giving the relatively homogeneous fiber networks. (From Ohkawa, K. et al. 2006.

Biomacromolecules

7:3291-3294. With permission.)

9.2.3 Chitosan-based Microsphere Scaffolds

Recently, microspheres have also been assessed as scaffolds for tissue engineering, and

new strategies, such as sintering and fusion methods, have been investigated to obtain

suitable scaffolds that mimic the tissue environment for cells. Most of the concepts based

on the use of such scaffolds require the implantation kind of the hybrid constructs through

a surgical procedure. The process of scaffold fabrication consisted of the following steps.

(1) Preparation of chitosan-based microspheres: polymer dissolving, spheres production

by extrusion of the solution to the precipitating bath, pH neutralization, scaffold forma-

tion, chitosan cross-linking, rinsing, and drying. (2) Microsphere scaffold formation:

TAble 9.1

Electrospun Chitosan Composites Nanofibers

Average Fiber

Diameter (nm)

Composites

Solvent

References

Chitosan/collagen

HFP/TFA

415-810 (−)

[21,22]

Chitosan/gelatin

TFA/DCM

100-220

[23]

Chitosan/agarose

TFA/DCM

140-1500 (+)

[24]

Chitosan/PEO

aq. AA

80-180

[25]

Chitosan/PLA

TFA

[26]

40-1200 (−)

Chitosan/PCL

Formic acid/acetone

112.9-139.6

[27]

Chitosan/PVA

aq. AA

20-100

[28]

Chitosan/PLGA

Chloroform/DMF

272

[29]

Note:

(+), diameter of composites increases with increasing chitosan content; (−), diameter

of composites decreases with increasing chitosan content.

HFP, 1,1,1,3,3,3-hexafluoroisopropanol; TFA, trifluoroacetic acid; DMF, N,N-dimethyl-

formamide; aq. AA, aqueous acetic acid solution; DCM, dichloromethane; PVA, poly(vinyl

alcohol); PEO, poly(ethylene oxide); PLA, poly(lactic acid); PLGA, poly(lactide-co-glycolide);

PCL, polycaprolactone.

Search WWH ::

Custom Search