Biomedical Engineering Reference

In-Depth Information

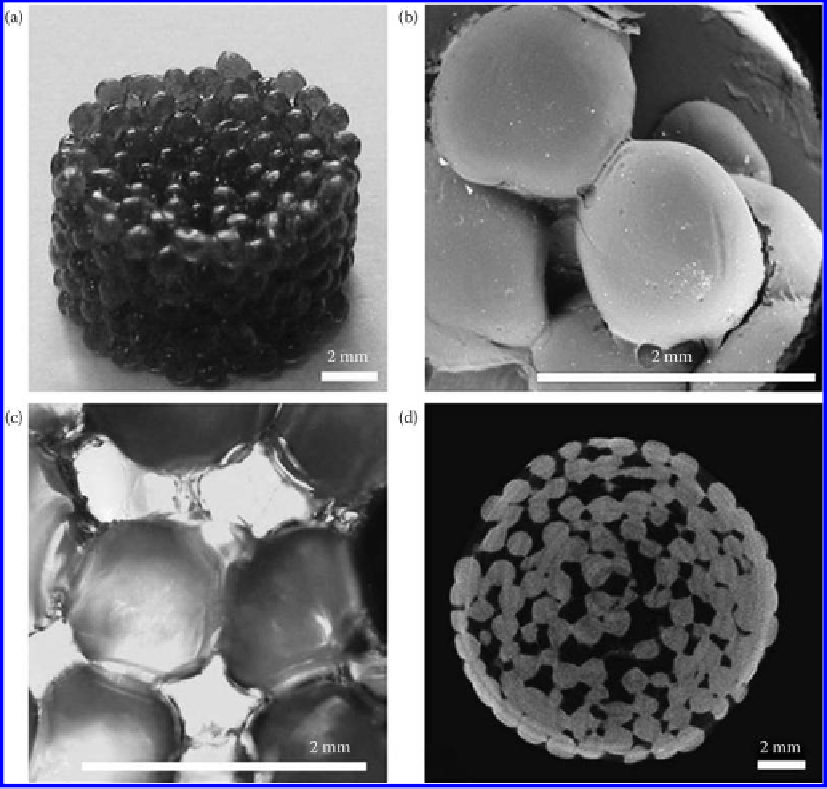

scaffolds were fabricated by packing and agglomeration of the microspheres. On the one

hand, chitosan-based microspheres can be packed with the use of a solvent. The acidic

solvent dissolves the external surfaces of the spheres so that they get stuck together and

their structure becomes tight and durable. As shown in Figure 9.6, strong union between

chitosan particles was obtained through acetic acid rinsing, which partially dissolved the

surface. Scaffold porous architecture is presented in the pictures. The average porosity

measured was about 40% [30]. On the other hand, packing of microspheres and their

aggregation can be realized at high temperature. Briefly, chitosan-based microspheres are

put into a stainless-steel mold. The mold was heated to a temperature above the glass

transition of polymer for a certain time period to achieve bonding between adjacent

microspheres. The bonding of chitosan microspheres was achieved due to the bioadhe-

sive character of the chitosan polymer that resulted in the union of adjacent particles at

Figure 9.6

(a) Morphology of scaffold manufactured by the presented method. (b) SEM microphotograph of agglomerated

scaffold. (c) Spheres interconnectivity observed by optical microscope. (d) One of cross-sections obtained by

µCT scanning.

Search WWH ::

Custom Search