Graphics Reference

In-Depth Information

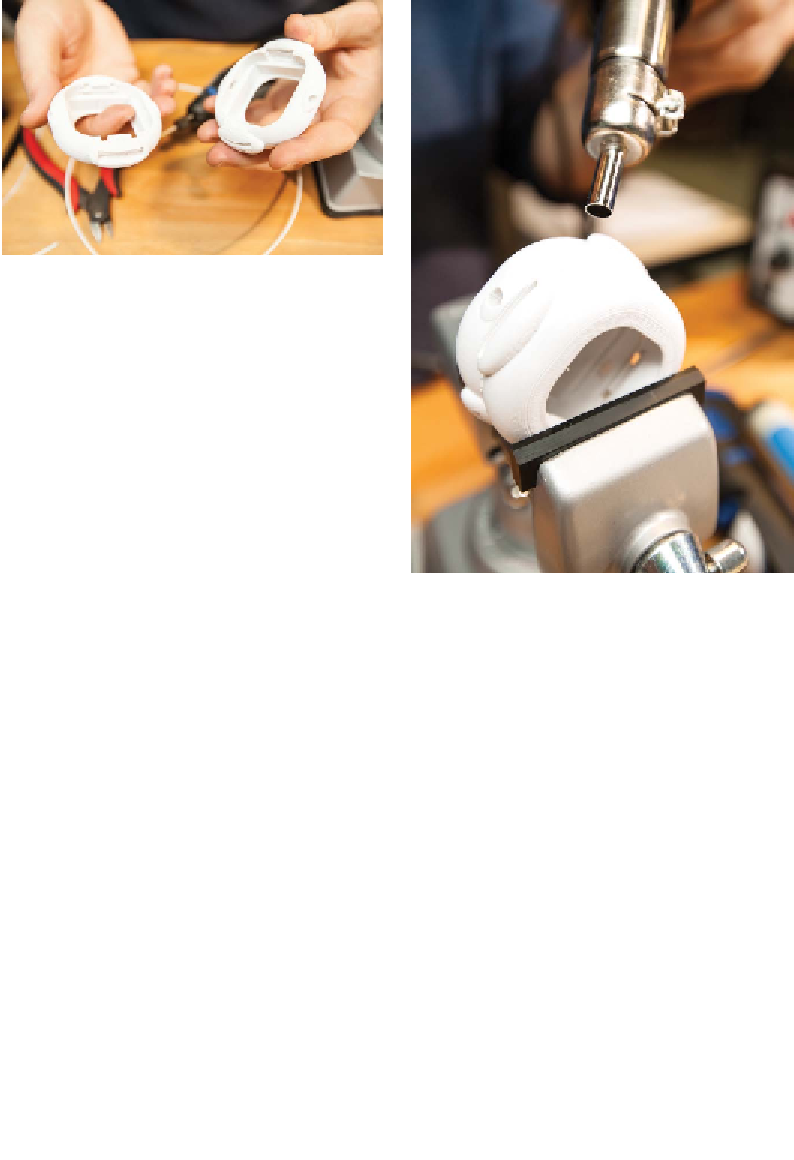

Figure 13-4.

Prepare parts for welding

Use a deburring tool or razor blade to bevel

the top edges of the seam where the parts

meet, forming a narrow, V-shaped channel

(

Figure 13-5

). Your goal is to create enough

room for three welding layers, from the bot-

tom of the bevel up to just above the surface

of the two parts. This method gives a stron-

ger bond than a weld that sits just on the

surface.

Figure 13-6.

Warm the parts with a heat gun

3. Tack-Weld the Parts in

Position

Now tack the parts together with a series of

short spot welds, moving around the joint

while holding the parts steady.

Spin up the rotary tool, and lower it until the

spinning filament grazes both surfaces of

the seam. When the tip of the filament be-

gins to deform, apply a little pressure

(

Figure 13-7

).

Figure 13-5.

Bevel the top edges of the seam, form-

ing a narrow, V-shaped channel

Warm both parts with low heat from a heat

gun (

Figure 13-6

). This helps them receive

the weld to the same depth. If one part is

much larger than the other, focus extra at-

tention on warming the larger piece.