Hardware Reference

In-Depth Information

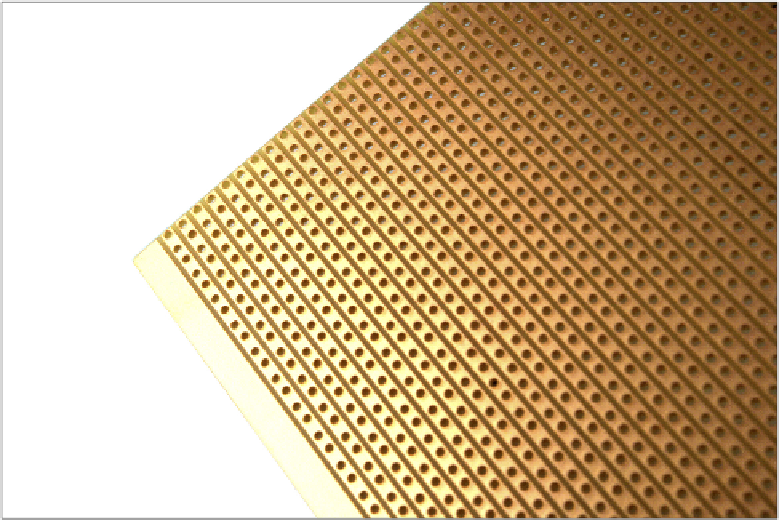

Figure 12-8:

he copper

tracks on the

underside of a

piece of

stripboard

Stripboard is extremely easy to use, which makes it a great stepping-stone to custom circuit

board design and manufacturing. However, you should be aware of the following before you

buy stripboard:

❍

here are diferent types of stripboard. Some stripboards have copper tracks on the

underside, which go all the way across a row or down a column, while other stripboards

are split into two separate rows with a gap in the middle like a breadboard. Yet another

type of stripboard, often called a project board, has no copper tracks at all and requires

the use of wires to join components together electrically.

❍

Stripboard can be made in diferent thicknesses and with diferent materials, and one

type of stripboard may be more suited to a particular project than another. For example,

a heatproof stripboard is good for a circuit that is going to be in a high-temperature envi-

ronment, while thicker stripboard should be used for circuits that may be exposed to

rough handling.

❍

To make the component layout on a stripboard neater, it's possible to break the tracks on

the underside to separate components electrically. his avoids wasted board space and is

an absolute necessity in more complex circuits—but to achieve the neatest results, you'll

need a small hand-held tool called a

track cutter.

Remember to add that to your shopping

list if you're planning on using stripboard, although a small drill bit can also be used.