Hardware Reference

In-Depth Information

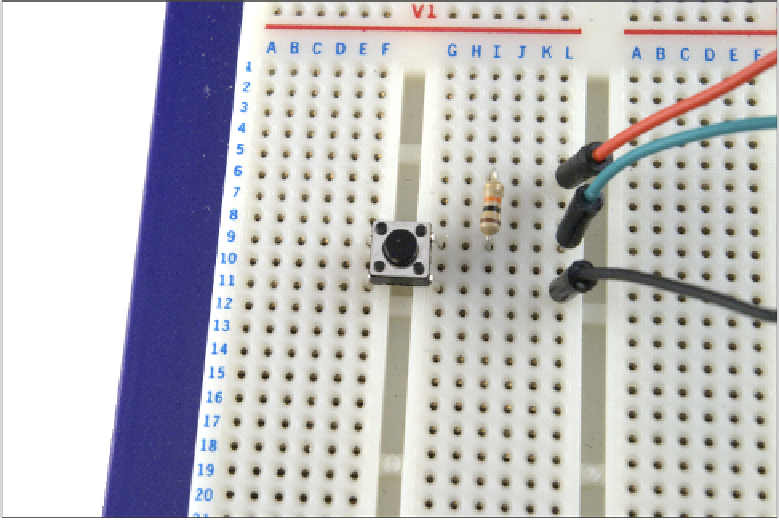

Figure 12-7:

A sample

breadboard

circuit, with

loose-itting

components

his, among other reasons, is why the Raspberry Pi itself is built on a

printed circuit board

(PCB)

rather than a breadboard—although the breadboard method was certainly used in the

early days of prototyping the device. It's possible to print and etch your own PCBs at home,

but there is a simpler intermediate step you can take: using

stripboard

to create permanent

stand-alone circuits.

At irst glance, stripboard looks similar to breadboard, because its surface is covered in small

holes at 2.54 mm spacing. Unlike a breadboard, however, there's no clever mechanism for

ensuring that electronic components placed into these holes stay in place—instead, you'll

have to solder them onto the stripboard. Stripboard is often referred to by the trade name

Veroboard,

which is a trademark of Vero Technologies in the UK and Pixel Print in Canada.

Creating a stripboard circuit has many advantages over using a breadboard. A sheet of strip-

board is signiicantly cheaper than an equivalently-sized breadboard, and it can be snapped

to size for smaller circuits. his also allows a single, large piece of stripboard to be used in the

creation of several smaller, independent circuits.

Because components are soldered onto stripboard, it's also signiicantly more robust than a

breadboard prototype. A stripboard circuit can be carried around from place to place with

little risk that one of its components will become dislodged and lost. Figure 12-8 shows a

piece of stripboard lipped to show the copper tracks on its underside.