Biomedical Engineering Reference

In-Depth Information

table 1.

Tensile properties of silk fiber.

Fiber types

Average Tensile Stress (MPa)

Average E-modulus (GPa)

Average strain (%)

Raw silk

Alkali Treated silk

227

319

9.56

15.45

23.53

25.67

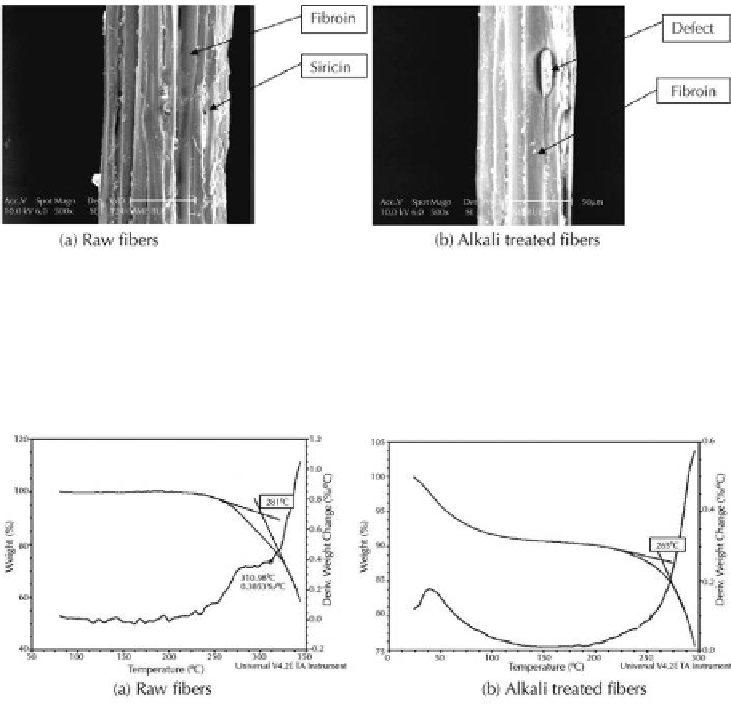

surface morphology of Fibers

Surface morphology of raw and alkali treated silk fibers was observed by using SEM.

It is shown in Figure 8. Raw silk surface contains fibroin and siricin (Figure 8(a)).

Siricin is a hard and gummy matter that binds fibroin together. Fibroin gives the fiber

strength. Fiber defects can be seen in Figure 8(b), which reduce the fiber strength. Silk

fibers after treated with alkali show rather smooth surface and reduction in diameter as

compared to raw fibers. Alkali treated silk fiber contains small amount siricin than raw

silk. For that reason, alkali treated silk fibers give better properties than raw silk fibers.

Figure 8.

Surface morphology of silk fibers (500X).

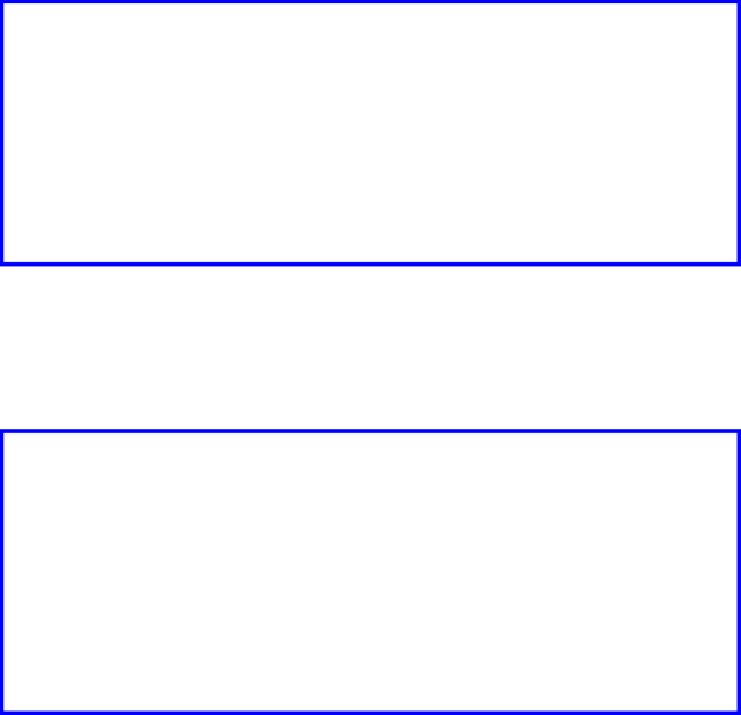

thermo-gravimetric analysis (tGa) of silk Fibers

From TGA curves of raw and alkali treated silk fibers (Figure 9), it is seen that raw silk

fiber is stable up to 281°C and alkali treated silk fiber is stable up to 265°C.

Figure 9.

Thermo-gravimetric analysis (TGA) curves of silk fibers.

Search WWH ::

Custom Search