Biomedical Engineering Reference

In-Depth Information

tensile testing of Composites

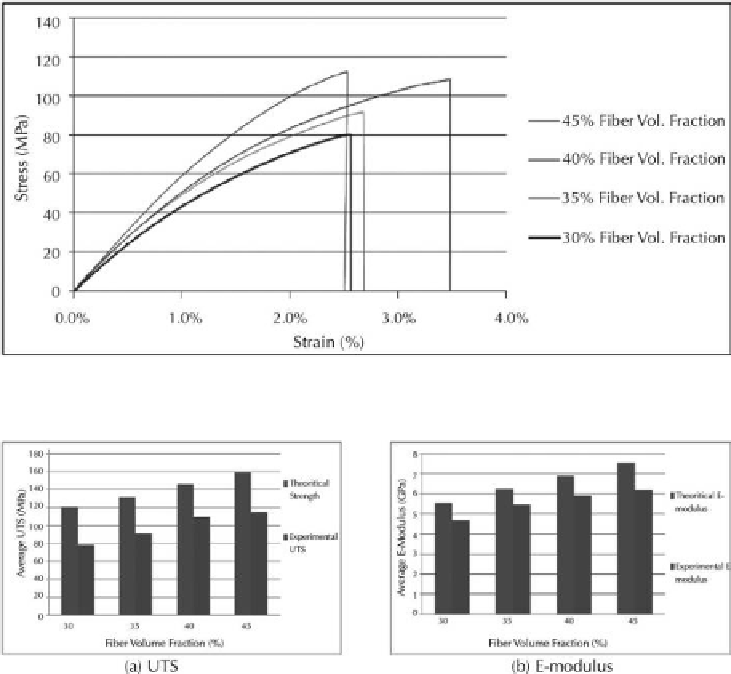

Stress-strain curves of unidirectional fiber-reinforced composites under longitudinal

loading are represented in Figure 10. It is seen from this Figure that ultimate tensile

strength (UTS), modulus and percentage elongation are maximum for fiber volume

fraction at highest end (45%), because the load applied to the fiber direction. Longi-

tudinal strength is dominated by fiber strength. The stress-strain mode that operates

for a specific composite will depend on fiber and matrix properties, and the nature

and strength of the fiber-matrix interfacial bond. Figure 11 represents the comparison

between theoretical and experimental strength and modulus; the experimental values

are lower than theoretical values. This is due to the poor fiber-matrix interface and

misalignment of continuous unidirectional fibers.

Figure 12

shows that longitudinal

strain increases with fiber volume fraction.

Figure 10.

Stress-strain curve for composites under longitudinal loading.

Figure 11.

Comparison between theoretical and experimental longitudinal strength and modulus.

Search WWH ::

Custom Search