Biomedical Engineering Reference

In-Depth Information

of test machine and to provide straight direction during test. This paper frame was

clamped in the machine jaws and cut the paper frame carefully before starting the test.

The crosshead speed maintained for silk fiber was 3 mm/min and a 5 N load cell was

used. A small tensile testing machine was used for testing with various span lengths of

5, 15, 25, and 35 mm.

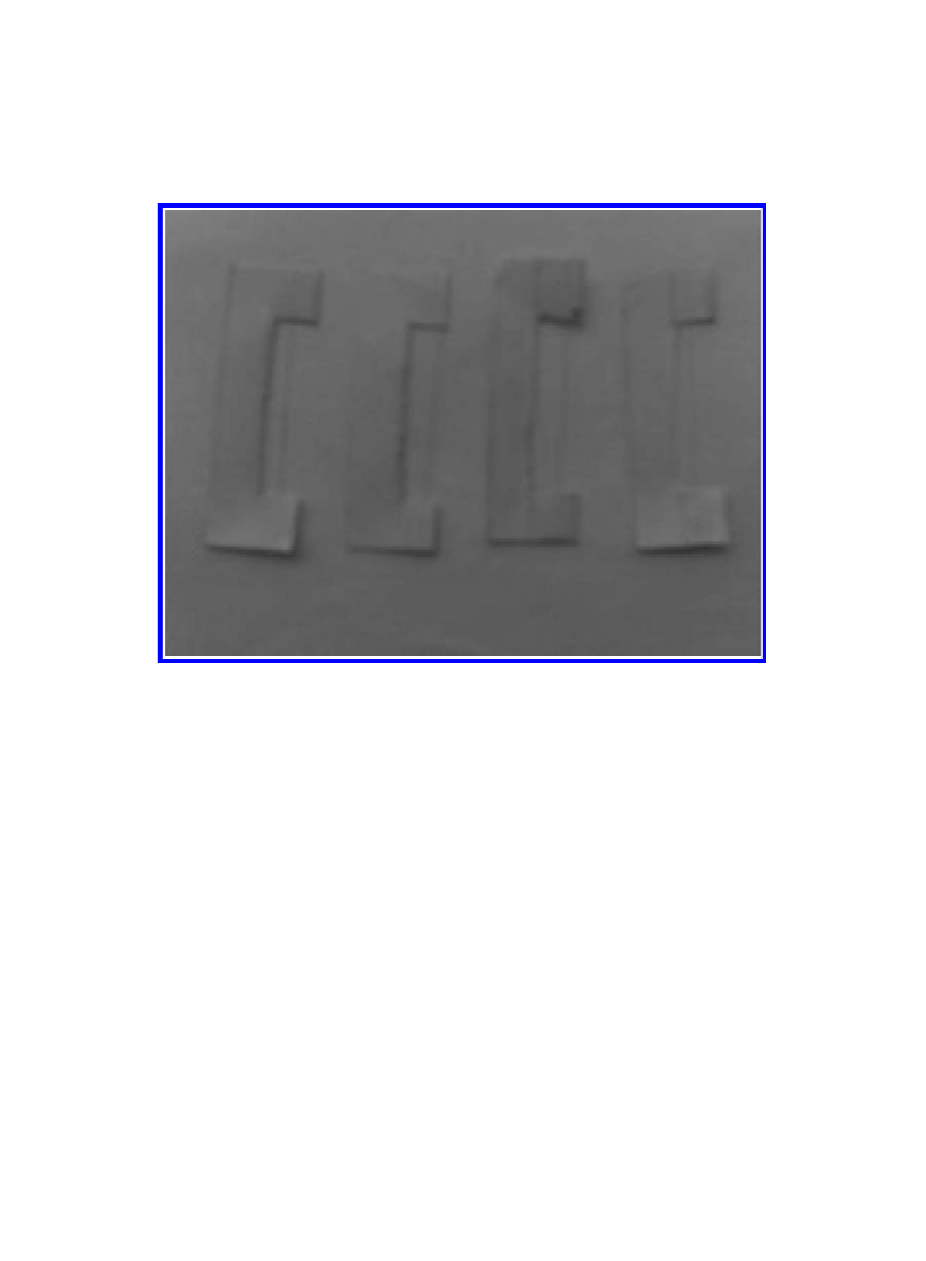

Figure 1.

Specimens for tensile test.

Tensile strength is calculated by following formula:

σ = F

max

/A

(1)

where,

σ = Tensile strength

F

max

= Maximum force

A = Cross sectional area

Cross sectional area, A was measured by using this formula:

A = π(d/2)

2

(For jute fibers (Mitra et al., 1998))

(2)

where, d is diameter.

Young's modulus, E was measured from the stress-strain curve.

Fabrication of Composites

Four types of composites were manufactured. Unidirectional silk fiber composites

were made using PP and MAPP matrix. By varying fiber volume fraction (30, 35, 40,

and 45%), 2 mm thick composites were manufactured.

Steps for manufacture are given below:

(a) At first, alkali treated silk fiber was weighted according to the required volume

fraction needed. The required amount of weight of silk fiber was weighted.

Search WWH ::

Custom Search