Biomedical Engineering Reference

In-Depth Information

(b) Sufficient amount of commercial PP was taken in a beaker and weighted. The

20% MAPP was added with it. To prevent voids, water bubbles, poor fiber

matrix adhesion, the PP was dried in an oven at about 100ºC for 3-4 hr.

(c) Mold surface was cleaned very carefully and Teflon sheet was placed over the

mold surface properly for the easy removal of the product.

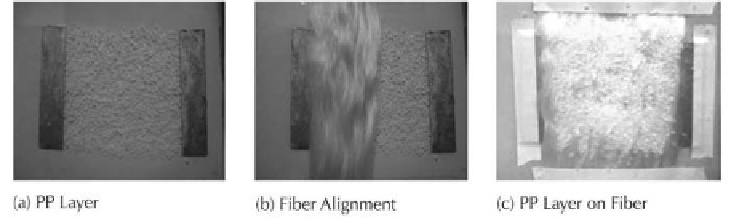

(d) A layer of PP granule with MAPP was placed in a female mould and 2 mm

thick die was placed surrounding the granule.

(e) Then one layer of continuous fibers was aligned parallel to each other onto

PP granule using glue at the edges of fiber (see Figure 2) and another layer

of fibers was placed over prior layer. And so on to produce as required fiber

volume fraction.

(f) Finally, another layer of mixture of PP and MAPP was placed onto silk fiber

layer.

(g) The female mould with aligned fiber with PP was covered by a male mould

with Teflon sheet.

(h) Plates were placed in hot pressing machine, 185°C temperature and 85 kN

pressure was applied simultaneously for about 15 min and then cooled slowly

using water-cooling system.

(i) At last, the specimen was carefully discharged from the mould.

Figure 2.

Unidirectional silk fiber reinforced composite fabrication process.

disCussioN aNd results

tensile testing of Fibers

Stress-strain curves of raw and alkali treated silk fibers (25 mm span) are shown in

Figure 3.

Also, uncorrected and corrected extrapolated curves (1/span vs. modulus,

strain to failure and span vs. tensile strength) for the spans of 5, 15, 25, and 35 mm

increase of span length, Young's modulus increased for uncorrected curves. Some slip-

page portion occurs during tensile testing (which is called machine constant and de-

noted by (α). Larger span length helps to minimize the slippage portion (α) compared

to smaller one as shown in

Figure 7.

Therefore, modulus of longer span is higher and

strain to failure is lower than smaller span. Total slippage portion of the machine can

be calculated by using the following equations:

Search WWH ::

Custom Search