Biomedical Engineering Reference

In-Depth Information

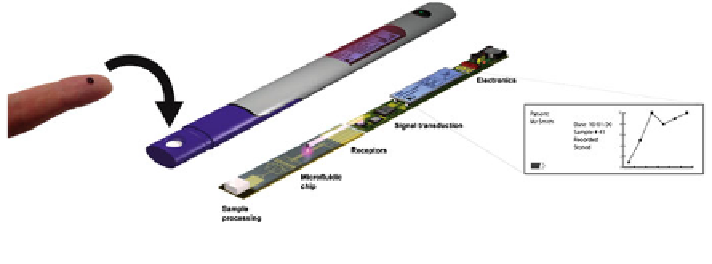

Fig. 1

A concept diagnostic device built around microfluidic technology. Adapted from [

34

]

2 Microfluidics in Brief

Microfluidic platforms are so called because they typically deal with fluidic reagents

contained within micrometre-sized channels or chambers. Nano- or picolitre vol-

umes are transported around these microchannels where they are filtered, mixed,

reacted and detected—ideally on the same device or 'chip'. Fluid transport is often

induced by applying a pressure difference by means of syringe pumps or pressure-

driven systems. Alternatively, electro-osmotic flow or capillary forces can be used

to move fluids. The latter is particularly interesting for POC devices because no

further external devices are required. Figure

2

depicts a number of different

microfluidic methods, including microchambers arrays that are commonly used to

direct fluids to specific positions on a microchip. Additionally, open systems based

on paper or specifically prepared surfaces are interesting alternatives to direct fluids

along predefined pathways; these will be discussed later in this chapter.

Fluid flow can be characterized by the dimensionless Reynolds number, which

provides the ratio of inertial to viscous forces within a system. Microfluidic sys-

tems usually have Reynolds numbers much less than 100, meaning that the viscous

forces dominate. As a result, fluid flow is laminar and without turbulence. In order

to carry out on-chip reactions, the reagents must first be mixed quickly and effi-

ciently. In a laminar flow system, mixing occurs via diffusion alone. Therefore, in

microchannels that are typically tens or hundreds of microns wide, proteins will

only take seconds to diffuse and mix compared to minutes in a macroscopic

system. Although this is not enough to resolve fast kinetics, it is sufficiently fast for

diagnostic tests, which usually involve simple binding reactions. Using micro-

fluidic technology may enable future devices to provide fast readouts of results.

Moreover, because additional components to promote mixing are not required, it

eliminates any expensive fabrication step.

Advantages. Systems that use microfluidic technology have several advantages

over the more traditional methods for chemical analysis, bioanalysis, and diag-

nostics, which can be directly derived when simply considering the changes in the

volume and surface areas when a system is scaled down.