Biomedical Engineering Reference

In-Depth Information

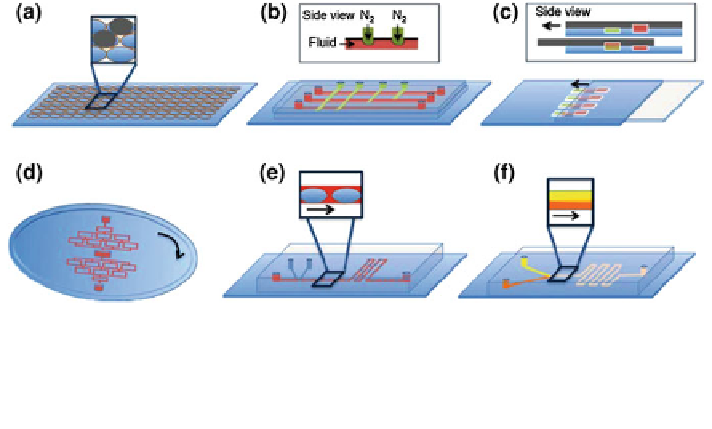

Fig. 2 Fluid handling using microfluidic systems. a Picolitre volumes in microarrays.

b Pneumatic valves to isolate microchannel sections. c Microchambers and microchannels can

be combined by moving separate layers. d Rotating devices use centrifugal forces to direct fluids.

e Water microdroplets within a moving oil phase. f Continuous flow where mixing is due to

diffusion [

59

]. Reproduced with permission of Informa Healthcare

(i) The small size of microfluidic devices makes them highly portable, thus

allowing them to be easily transported and used in the most remote locations. (ii)

Perhaps the most important advantage is the reduced cost that comes from the

small fluid volumes contained within the channels. Compared to the conventional

benchtop systems that typically use micro or millilitres, microfluidic systems only

require nano- or picolitre volumes to fill the channels. Not only does this reduce

the cost of the regents involved, but it also means that diagnostic tests can still be

performed efficiently when only limited amounts of the sample are available, ideal

for POC applications. (iii) Faster transport times can be realised by having short

distances, and therefore integrated processes can be performed very quickly. (iv)

The volume and surface area scale with the cube and square of the edge length,

respectively, resulting in an increased surface-to-volume ratio in microfluidic

channels. Therefore, surface-based biochemistry, e.g. immunoassays, can be per-

formed very efficiently. Scaling down also provides the additional benefit of

increased thermal transport, allowing the small volumes to be quickly heated and

cooled to provide thermal gradients or precise temperature regulation during a

reaction. This is also an important aspect for applications that require an electrical

field, which may generate heat, e.g. electrophoresis. (v) Additionally, the dimen-

sions of the microchannels are ideally suited to the handling and analysis of cells

and cell organelles.

Fabrication and materials. Although microsystems in the range of a few

hundred micrometres can usually be manufactured with conventional instruments

and milling machines, further downscaling to dimensions below *300 lm

requires alternative fabrication processes. Most devices in these dimensions are

made by means of photolithography. This requires clean room facilities and

expensive equipment to achieve good quality structures. For further reading on

fabrication methods, the textbook by M. Madou is recommended [

60

].