Environmental Engineering Reference

In-Depth Information

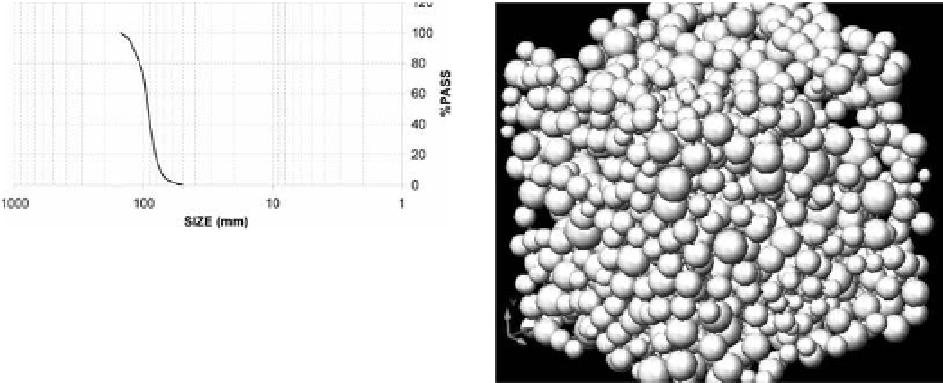

Figure 1. Grain size distribution for the particles that

formed the macroporous material.

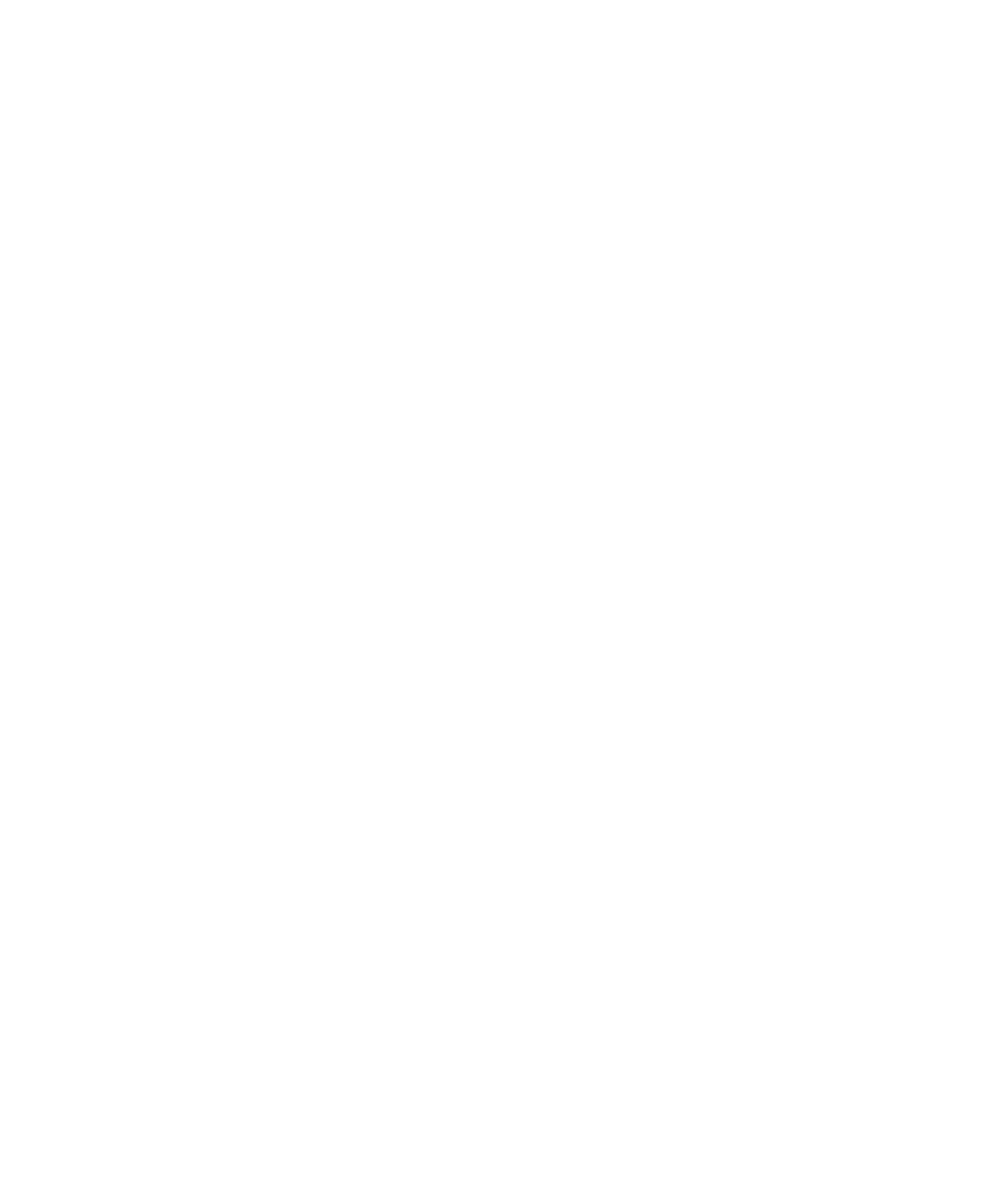

Figure 3. example of a numerical macroporous mate-

rial of 1300 particles.

but a wall-beam model instead. By doing this,

it is obtained a joining tablet material in each

previously existing contact.

after all this process, a macroporous medium

is obtained. in Figures 2 and 3 it is shown some

examples of the macroporous created. The particles

are in white and the joining material in red. The

joining material is not in its real dimensions, it has

only been included to observe which particles are

in contact and which are not.

Figure 2. example of a numerical macroporous mate-

rial of 1300 particles.

3

eQUaTions oF The MoDel

in this point, the equations that command the

behavior of the macroporous material are shown.

in general, the macroporous can be under any kind

of load in each of its boundaries. But this research

is focused in modeling a consolidated triaxial test.

From the point of view of the strength, the

response of the medium is conditioned by the

joining material and its collapse. To model this

material, it has been assumed that a wall-beam,

similar to a tablet shaped material, under axial and

shear stresses is a good enough approximation.

The parameters considered for this material has

been the following ones:

probability of size is directly proportional to the

percentage retained by the size of each fraction,

according to the curve.

5. after this process, a cubic cell filled with

particles is obtained. These particles are in con-

tact but a joining material is filling those contacts,

keeping the particles joined and cohesioned. in

order to introduce this joining material a gap

is needed between the particles in contact. To

do this, a random uniform distribution between

two values was used to reduce the diameter of

the particles accordingly to it.

6. an elastic and breakable joining material was

inserted in the previously existing particle to

particle contacts. The joining material was

assimilated to square section prisms with a

section side (B) and a length (h) that was

determined in the fifth step. The B dimension

is randomly created using a random uniform

distribution between 2 and 6 times the length.

Doing this, a 2 to 6 B/h ratio is obtained. This is

necessary because a beam model is not wanted

E

= 600 MPa

(1)

V

= 0.2

(2)

σ

c

= 1 MPa

(3)

where: e is the Young´s modulus, ν is the Poisson's

ratio and σ

c

is the unconfined compressive

strength.