Biomedical Engineering Reference

In-Depth Information

all models. If we posit that the urethane elastomer membrane of

rectangular cross section of Fig. 4.10 is under a tensile force

F

when

placed inside the polariscope in Fig. 4.6 instead of the vasculature

model, the longitudinal stress

T

1

is given by

T

1

F

LD

(4.26)

where

L

and

D

are the width and thickness of the membrane's

cross section. Because in this case

T

2

equals zero, the stress in the

membrane may be calculated using equation (4.4) or (4.26).

Quarter-wave plates

0L

ex

L

ex

L

ex

Force

Sensor

L

ex

L

ex

Urethane Membrane

F

L

White

Light

Source

Urethane

Membrane

Region of Interest

a)

5

0mm

b)

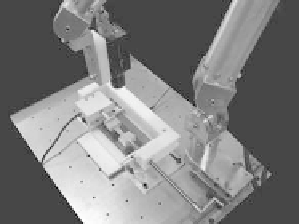

Figure 4.10

(a) Variable tension device for photoelastic coeficient

calculation. (b) Membrane used for deducing the photoelastic

coeficient of urethane elastomer.

Therefore, we are able to calculate the photoelastic coeficient of

urethane elastomer

C

using

Re

L

C

(4.27)

F

We built the device shown in Fig. 4.10a, composed of a C-clamp

and a force sensor for gradually applying and measuring tension

to the membrane. Some of the elements of the polariscope are

shown in this igure. A total of 19 samples were captured obtaining

simultaneous measurements of Re,

F

and

L

. Figure 4.10b shows the

membrane inside the polariscope when

F

= 2.1 N, Re is measured

after calibrating the camera from the average of green light intensity

at the region of interest and equation (4.22). Tension was applied to

the membrane in a range of 0.3-3.7

N, while the photoelastic images

were captured for visualizing the irst fringe.

L

is obtained from the

image captured when force is applied to the membrane. For this

experiment,

M

G

was found to be 521

nm. Figure 4.11 shows the plot of

Search WWH ::

Custom Search