Biomedical Engineering Reference

In-Depth Information

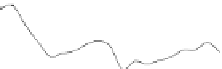

variation in the normalized green light intensity with applied force,

showing that complete irst fringe was captured, and the value of

the photoelastic coeficient obtained for each sample. Their average

value is 1.284

×

10

-9

Pa

-1

.

-09

1

1.50e

0.8

-09

1.40e

0.6

-09

1.30e

0.4

-09

1.20e

0.2

-09

1.10e

0

0.5

1

1.5

2

2.5

3

3.5

4

0

0.5

1

1.5

2

2.5

3

3.5

4

Applied Force (N)

Applied Force (N)

Figure 4.11

Variation of the green light intensity in urethane elastomer

membrane with the applied force, showing the irst fringe

(left). Variation of the photoelastic coeficient of NIPOLAN

5120 dyed yellow with the applied force (right).

4.7

Photoelastic Stress Analysis Error

Quantification

The difference between longitudinal and tangential stress for a

cylinder wall with inner pressure

P

is given by the following equation

[9]:

TT

¥

§

¦

µ

·

¶

2

rP

D

rD

rD

/

(4.28)

1

2

2

2

where the cylinder outer radius is

r

and its wall thickness is

D/

2. If

P

>

40

mmHg for the blood vessel model, the stress on the model wall

is described by equation equation (4.28).

When a phantom is placed into the polariscope inside a glycerin

bath, stress on the model wall may be calculated using equations

(4.4, 4.22) or with equation (4.28) by measuring Re,

D

and

r

.

Photoelastic measurement system error may then be quantiied

using the deformation measurements.

P

was increased within the blood vessel model using a syringe

and measured using a sensor for pressures below 200

mmHg

(Fig.4.12). For a range from 40-189

mmHg average stress in the

region of interest (ROI) was calculated using both methods for 16

samples (Fig. 4.7). Values of green were measured in ROI for each

sample.

Search WWH ::

Custom Search