Biomedical Engineering Reference

In-Depth Information

are produced inside the particles or on their surfaces. As the milling

duration increases, the content fraction of such intermediate

compounds increases, leading to a inal product whose properties

are the function of the milling conditions.

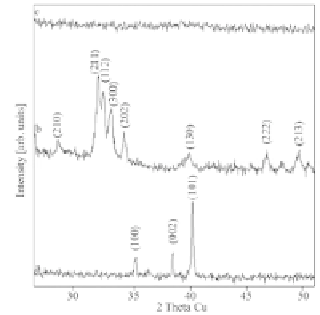

Figure 7.1

XRD spectra of Ti and HA (10 vol%) powders mechanically

alloyed: (a) Ti — 0 h, (b) HA — 0 h, (c) Ti-HA — 44 h MA [23].

Figure 7.2

TEM micrographs and electron diffraction patterns (insets) of

the milled Ti-10 vol% HA sample for 44 h — typical amorphous

fragment [23].

The microstructure of milled titanium and hydroxyapatite

powder was also studied by TEM. The sample milled for 44 h was

mostly amorphous (broad rings in the SEAD pattern) as appears

from high-resolution image (Fig. 7.2). Apart from prevailing

amorphous phase, the milled powders contained a small amount

of ine-crystalline and crystalline phases. Lack of any sharp

relections in the XRD pattern (Fig. 7.1c) suggests that the amount