Biomedical Engineering Reference

In-Depth Information

of the crystalline phase is very low and/or it forms during TEM

observation. During TEM studies, it has been found that the

amorphous powders was unstable upon exposure to electron beam

and underwent some crystallization.

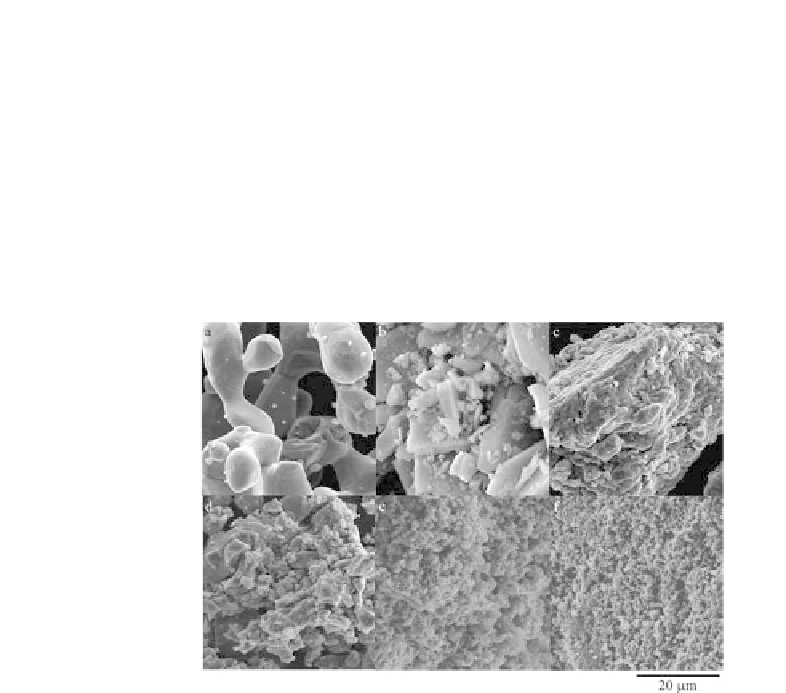

The SEM morphologies of the fabricated Ti-10 vol% HA powder

mixtures, at the various stages during milling, are shown in Fig. 7.3.

It can be seen that after 10 h of milling, the powder shows inhomo-

geneous size distribution (Fig. 7.3d). With the increase of milling

time, the size of the mixed powders decreases gradually and the

microstructure is

more homogenous (Fig. 7.3e,f).

Figure 7.3

SEM images show morphologies of powder mixtures of

Ti-10 vol% HA composite at the various stages during milling:

(a) Ti — 0 h, (b) HA — 0 h (c) Ti-HA — 3 h, (d) Ti-HA — 10 h,

(e) Ti-HA — 20 h, (f) Ti-HA — 44 h [23].

The formation of the bulk nanocomposites was achieved by

cold uniaxial pressing and sintering of the amorphous materials.

In all cases, XRD analysis of Ti-HA nanocomposites showed the

presence of α-Ti (hexagonal-type structure), but hydroxyapatite no

longer exists (Fig. 7.4). When 10 or 20 vol% of hydroxyapatite is

added to titanium, the lattice constants of Ti increases, as manifested

by a shift of the diffraction peaks of the (1 0 0), (0 0 2), and (1 0 1)

crystal planes of titanium towards smaller angles in comparison

with pure microcrystalline titanium. Calcium has higher atomic

diameter in comparison to titanium, so solid solution of Ca in Ti was