Biomedical Engineering Reference

In-Depth Information

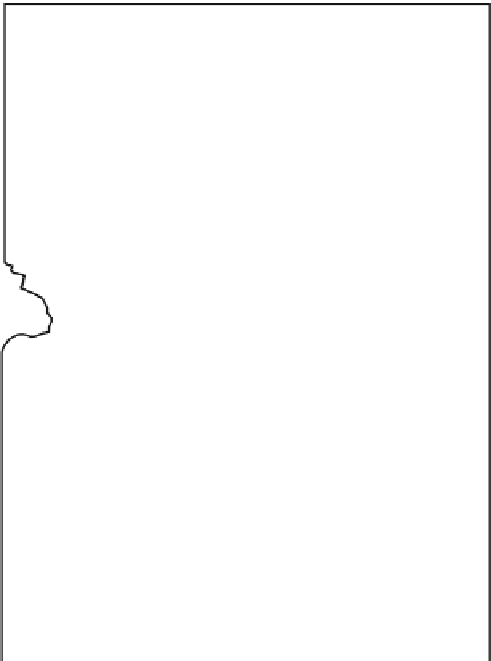

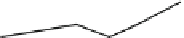

Thousands of atoms

may move

Sputtered

atoms

from

substrate

Ti

+

50 KeV

Vacancies

created

Reflected

primary ions

Heating in

surface region

Ti

distribution

with depth

Fig. 3.2.14-5 Some considerations for the ion implantation process.

properties (Picraux and Pope, 1984; Colligon, 1986;

Sioshansi, 1987; Nastasi

etal.,

1996).

Specific examples of biomaterials that have been

surface altered by ion implantation processes are plenti-

ful. Iridium was ion implanted in a Ti-6Al-4V alloy to

improve corrosion resistance (Buchanan

et al.,

1990).

Nitrogen implanted into titanium greatly reduces wear

(Sioshansi, 1987). The ion implantation of boron and

carbon into type 316L stainless steel improves the high

cycle fatigue life of these alloys (Sioshansi, 1987). Silver

ions implanted into polystyrene permit cell attachment

(Tsuji

et al.

, 1998).

multilayer structures can be created. Some compounds

that form organized LB layers are shown in

Fig. 3.2.14-7

.

The advantages of films deposited on surfaces by this

method are their high degree of order and uniformity.

Also, since a wide range of chemical structures can form

LB films, there are many options for incorporating new

chemistries at surfaces. The stability of LB films can be

improved by cross-linking or internally polymerizing the

molecules after film formation, often through double

bonds in the alkyl portion of the chains (Meller

et al.,

1989). A number of research groups have investigated LB

films for biomedical applications (Hayward and Chap-

man, 1984; Bird

et al.

, 1989; Cho

et al.

, 1990; Heens

et al.

, 1991). A unique cross between silane thin films and

LB layers has been developed for biomedical surface

modification (Takahara

et al.

, 2000). Many general re-

views on these surface structures are available (Knobler,

1990; Ulman, 1991).

LB deposition

The (LB) deposition method overcoats a surface with

one or more highly ordered layers of surfactant mole-

cules. Each of the molecules that assemble into this layer

contains a polar ''head'' group and a nonpolar ''tail'' group.

The deposition of an LB film using an LB trough is il-

lustrated schematically in

Fig. 3.2.14-6

. By withdrawing

the vertical plate through the air-water interface, and

then pushing the plate down through the interface,

keeping the surface film at the air-water interface com-

pressed at all times (as illustrated in

Fig. 3.2.14-6

),

SAMs

SAMs are surface films that spontaneously form as

highly ordered structures (two-dimensional crystals) on

specific substrates (Maoz

et al.

, 1988; Ulman, 1990,

1991; Whitesides

et al.

, 1991; Knoll, 1996). In some