Biomedical Engineering Reference

In-Depth Information

Fig. 3.2.9-9 Microstructure of Co-based MP35N, ASTM F562,

Biophase. (Photo courtesy of Smith & Nephew Richards, Inc.,

Memphis, TN.)

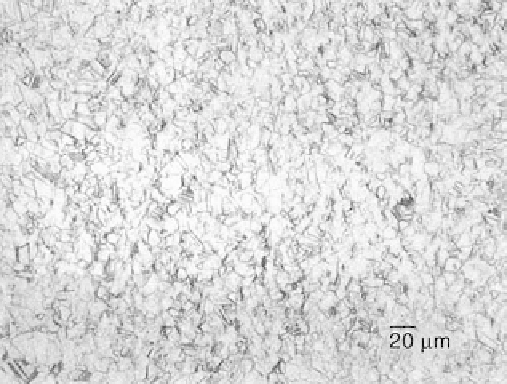

Fig. 3.2.9-8 Microstructure of the Co-Cr-Mo ASTM F75 alloy

made via HIP, showing the much smaller grain size relative to that

in Fig. 6. (Photo courtesy of Zimmer USA, Warsaw, IN.)

Titanium-based alloys

Fig. 3.2.9-9

) and the HCP platelets further impede

dislocation motion, the resulting structure is significantly

strengthened (

Table 3.2.9-2

). It can be strengthened

even further (as in the case of Richards Biophase) by an

aging treatment at 430-650

C. This produces Co

3

Mo

precipitates on the HCP platelets. Hence, the alloy

is truly multiphasic and derives strength from the com-

bination of a cold-worked matrix phase, solid solu-

tion strengthening, and precipitation hardening. The

resulting mechanical properties make the family of

MP35N alloys among the strongest available for implant

applications.

Composition

CP titanium (ASTM F67) and extra-low interstitial (ELI)

Ti-6Al-4Valloy (ASTM F136) are the two most common

titanium-based implant biomaterials. The F67 CP Ti is

98.9-99.6% Ti (

Table 3.2.9-4

). The oxygen content of CP

Ti (and other interstitial elements such as C and N) affects

its yield and its tensile and fatigue strengths significantly,

as discussed shortly.

With Ti-6Al-4V ELI alloy, the individual Ti-Al and

Ti-V phase diagrams suggest the effects of the alloying

Table 3.2.9-4 Chemical compositions of Ti-based alloys for implants

Material

ASTM

designation

Common/

trade names

Composition

(wt.%)

Notes

Pure Ti, grade 4

F67

CP Ti

Balance Ti

max 0.10 C

max 0.5 Fe

max 0.0125-0.015 H

max 0.05 N

max 0.40 O

CP Ti comes in four grades

according to oxygen content-

Grade 1 has 0.18% max O

Grade 2 has 0.25% max O

Grade 3 has 0.35% max O

Grade 4 has 0.40% max O

Ti-6Al-4V ELI

*

F136

Ti-6Al-4V

88.3-90.8 Ti

5.5-6.5 Al

3.5-4.5 V

max 0.08 C

max 0.0125 H

max 0.25 Fe

max 0.05 N

max 0.13 O

*

A more recent specification can be found from ASTM, the American Society for Testing and Materials, under F136-98e1 Standard Specification for Wrought Titanium-6

Aluminium-4 ELI (Extra Low Intersitial) Alloy (R56401) for Surgical Implant Applications.