Biomedical Engineering Reference

In-Depth Information

inpatient procedures (631,000 procedures), second on

the list was excision or destruction of an intervertebral

disk (250,000 procedures). Since the latter often in-

volves a bone graft of some kind (from the same patient

of from a bone bank) and internal fixation with plates

and screws, this represents yet another clinical pro-

cedure involving significant use of biomaterials. Overall,

including all clinical specialties in 1988, statistics

showed that about 11 million Americans (about 4.6% of

the civilian population) had at least one implant (Moss

et al.,

1990).

In view of this wide utilization of implants, many of

which are metallic, the objective of this section is to

describe the composition, structure, and properties of

current metallic implant alloys. Major themes are the

metallurgical principles underlying structure-property

relationships, and the role that biomaterials play in the

larger problem of design, production, and proper utili-

zation of medical devices.

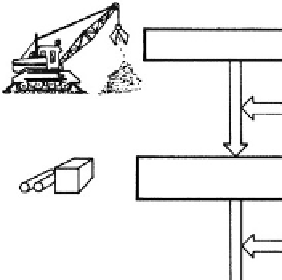

Steps in the fabrication of implants

Understanding the structure and properties of metallic

implant materials requires an appreciation of the metal-

lurgical significance of the material

0

s processing history.

Since each metallic device will ordinarily differ in exactly

how it is manufactured, generic processing steps are

outlined in

Fig. 3.2.9-1A

.

Metal-containing ore to raw

metal product

With the exception of the noble metals (which do not

represent a major fraction of implant metals), metals

exist in the Earth

0

s crust in mineral form wherein the

metal is chemically combined with other elements, as in

the case of metal oxides. These mineral deposits (ore)

must be located and mined, and then separated and

Mineral deposits (ore)

Mining

Ore separation/concentration

Chemical extraction of metal

Refining of "pure" metal

Alloying to specification

Metallic raw material

in bulk form (e.g. ingots)

Casting

Forging

Rolling

Powder production

Heat treating

Stock shapes (e.g. bar wire

plate, sheet, tube, powder)

Fabrication

Investment casting

Cad/Cam

Grinding

Powder metallurgy

Preliminary implant device

Surface preparations

Porous coatings

Nitriding

Polishing

Sand blasting

Final implant device

Cleaning

Quality control

Packaging

Market

A

B

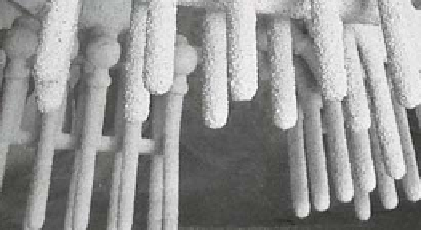

Fig. 3.2.9-1 (A) Generic processing history of a typical metallic implant device, in this case a hip implant. (B) Image of one step during the

investment casting (''lost wax'') process of manufacturing hip stems; a rack of hip stems can be seen attached to a system of sprues

through which molten metal can flow. At this point, ceramic investment material composes the mold into which the molten metal will flow

and solidify during casting, thereby replicating the intended shape of a hip stem.